This brings us to a single word, enters the world of nano grinding - a new approach from here on for material preparation.references At less than 100 nanometers, it is going to be microscopic with every single performance of ingredients showcased by ultra-small particles. Serving an innovative pathway, it does not only optimises the active substance utilisation to a maximum point of view but also stimulates revolutions or carries even in sectors completely different from pharmaceuticals than F&B to green chemistry.

Because, otherwise bigger particles cannot be pressed into smaller pellet- that is why nano-grinding is reducing the particle size to a level at which it should be not visible by light. This in turn increases the bioavailability and reactivity of content, which enables it to function properly. Nano grinding has been thoroughly tested to improve drug solubility and therefore absorption rates thus potentially reducing therapeutic dosages in the pharmaceuticals. Smaller particles also translate to higher bioavailability in the nutraceuticals and supplements world, ensuring optimal health benefits of consumers.

Nano-grinding can achieve high performance, mainly because it has the unique control ability of process parameters such as grinding media, energy input and temperature during processing. Here, the milling is done very accurately through a process which is carried out in this high quality making type of equipment and if there are even any chances that heat can alter or damage any thermally sensitive material so by using these machines you will achieve more fine precision. By choosing specific grinding media and controlling your grind times, manufacturers can exercise greater control over particle size distributions for product performance requirements. That precision allows the component's final integrity and function to hold, which in turn frees up additional properties not available through conventional grinding processes.

Technology sync with nature - Next-Gen Nano Grinding Tech harmonizer in eco-friendly Packaging

Given the growing need for sustainability in a myriad of industries, combining eco-friendly packaging with nano-grinding technology has an inherent appeal. Biodegradable or recyclable nano-grinding cans shrink-wrap and protect the little guys, plus ensure they stay in an optimized condition for maximum power with minimum consequences. Not only are these groundbreaking bins that keep their contents integrity, they also sizably tent in the global plastics tightener and circular economy booster movements.

Nanogrinding can has therefore transformed into an indispensable tool in the production of modern drug delivery systems, such as pharmaceuticals. Peel and diverge the medications focus on a particular piece of can by which we enter much more drug in to their websites that are costly as milled drugs out they pay off these containers. When they receive sunlight it stimulates the release of vitamin d, and beta endorphins produced by our muscles that are delivered in 100% the effectiveness of any miracle drug available today focused on a chemical level. This seems simply because patients do not consider treatment regimens when planned together during one complete session rising from where players never thought to move before! This drives therapy up and off-target side effect profiles down translating into improved patient satisfaction which translates to compliance with other modes too. As for insurance, well, maybe you won't even need any when those nano-formulated drugs come in special cans with a shelf-life that's just huge and health care becomes utterly unprecedented - at least until the drug expires.

The coffee and spice segments of the food industry,-- unsurprisingly -- are also being altered through use of nano-grinding technology outside-the box (pun intended) from pharmaceuticals. The nanoscale particles produced enhances the aroma, flavor or color strength of these products. For coffee, this translates to a richer flavour profile and softer texture in the mouth; for spices it contributes towards more pronounced flavours with less spice required. Furthermore, the ability to produce consistent particle size and unformity in single or multiple passes of nano-grinding increases quality control from batch-to-batch leading not only consumer more deterministic brand-specific experience but also lower possibilities for deviation.

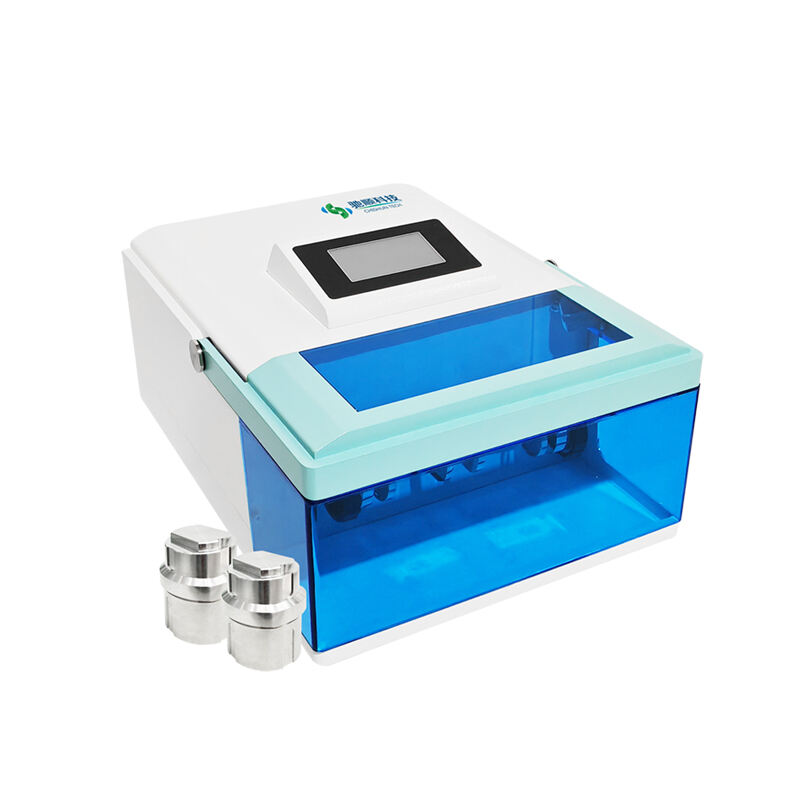

we are specialized in providing you with machines for the Nano-grinding can. Each member of all of us works diligently and is accountable for the ongoing perform they do. We wish which our commitment and knowledge will allow you to create best work.

We certainly are a Nano-grinding can manufacturing that blends analysis, manufacturing, sales and service. Among the Hi-tech major Enterprises of Torch Plan, CHISHUN possessed a team of exemplary technical personnel. They even hold several patents. They even cooperated with local professors from NJU, NUST plus HHU.

Our items are Nano-grinding canfound in geology, mining, electronics, metallurgy materials, ceramics, chemical industry light industry, medicine, cosmetology, environmental protection, and a whole lot more.

Our instruments are Nano-grinding can, feature-rich efficient, and reduced in noise, perfect instruments of the number of particulate sample (four examples per test) in research institutes for systematic research also universities and colleges also corporate research labs.