Equipment Matters When it comes to doing experiments for R & D purposes, you need the right tools. This is where a laboratory ball mill machine comes in. These are designed to grind a wide variety of materials using either an abrasive media that can easily be loaded and refilled. With a ball mill machine, test researchers can get the right material at one time and test several times, which is very efficient with the assistance of them along with dry or wet grinding.

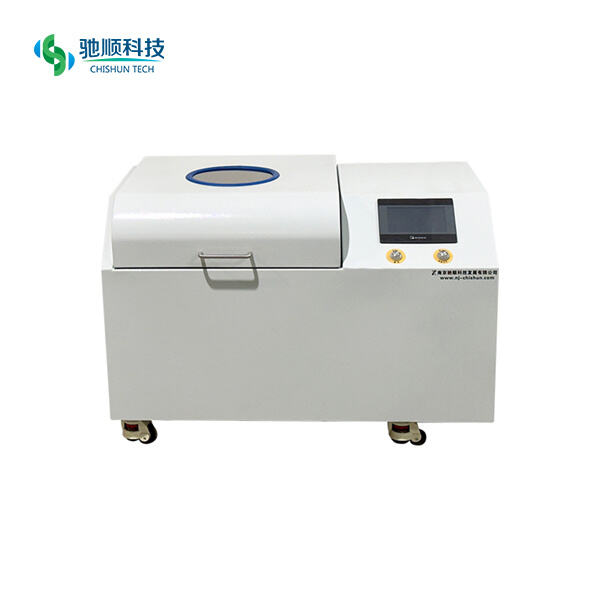

If you are looking for a lab ball mill that can meet your system’s needs, it is time to look into Chishun’s products. As one of the most professional sample preparation grinding, milling of sample preparation, sieving of sample preparation and assisting of sample preparation manufacturers in China, we warmly welcome you to buy bulk high quality products in stock here from our factory. Their applications include but not limited to scientific research, metallurgy, and electronic industries as well as environmental engineering. With more than 40 patents and the continuous technological innovation, the pursuit of product quality is a world-class manufacturer in prominent position.

Several of factors enter into the proper selection of a ball mill for an experimental research. The first thing to determine when you're setting up a ball mill is exactly what you are grinding, both the type of material your grinding and the materials can also get new ceramic balls if they pump out (taking 2-3 weeks inside an anywhere filled with finely enough powder). The second thing that you need to consider is the desired particle size and what sample type you want to mill, which will help determine the size and capacity of a ball mill appropriate for your project. Finally, take into consideration how much you want to spend and any extras (like speeds or programmable settings) you'd like. You must carefully consider all factors so you can decide the best ball mill that will suit your needs for use.

Material Testing Lab Equipment Trends and Innovations The market for material testing lab equipment is developing day by day with new trends and innovations cropping up frequently. 1 (Spr) A key trend in recent years has been the inclusion of automation and digital technology into laboratory equipment, leading to greater efficiency and accuracy. 2.2.Other trends Other trends appear, such as multifunctional equipment that accomplishes several tasks and prevents the multiple acquisition of lab machines. There is also an increasing emphasis on sustainability in the design and production of laboratory equipment as well as sustainable raw materials used in their manufacturing. Staying ahead of these trends is key in order for your laboratory to contain the most up to date advanced material testing equipment.

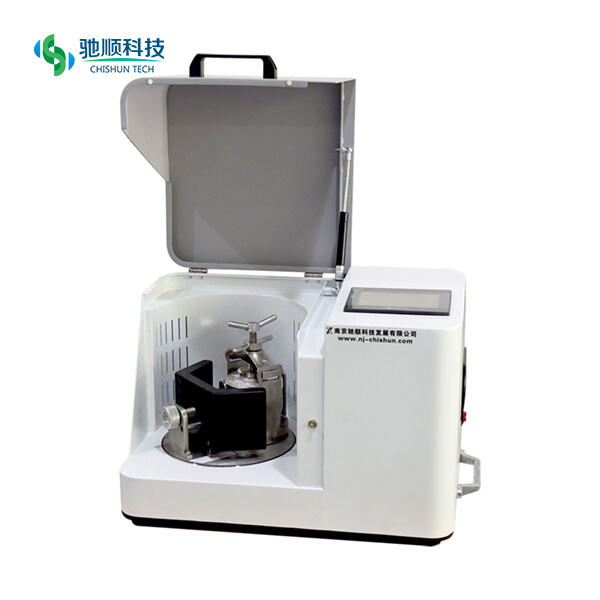

A lab ball mill is a grinding machine to grind all kinds of solid or liquid minerals/ores (rocks/stones) to smaller particle sizes. It is a necessary step for preparing homogeneous samples for testing and analysis.

To clean a laboratory ball mill machine, you have to first clear the grinding chamber and then remove any leftover particles or material that remains in its components. Lubrication of moving components and inspection for rubbing operation is suitably advised.

The particle size obtained by a laboratory ball grinding machine is significant for the test and analysis of the physical state of the material. Other experiments may rely on a certain particle size for accurate results, so precise grinding is key.