There was a very modern machine named ball rolling mill, A long time ago... This unique machine was used to form a variety of shapes and sizes from steel. It is very important for a lot of the jobs we see in our world todqy. Its functionality is diverse as it can be found in building cars we drive everyday and large buildings people work to live.

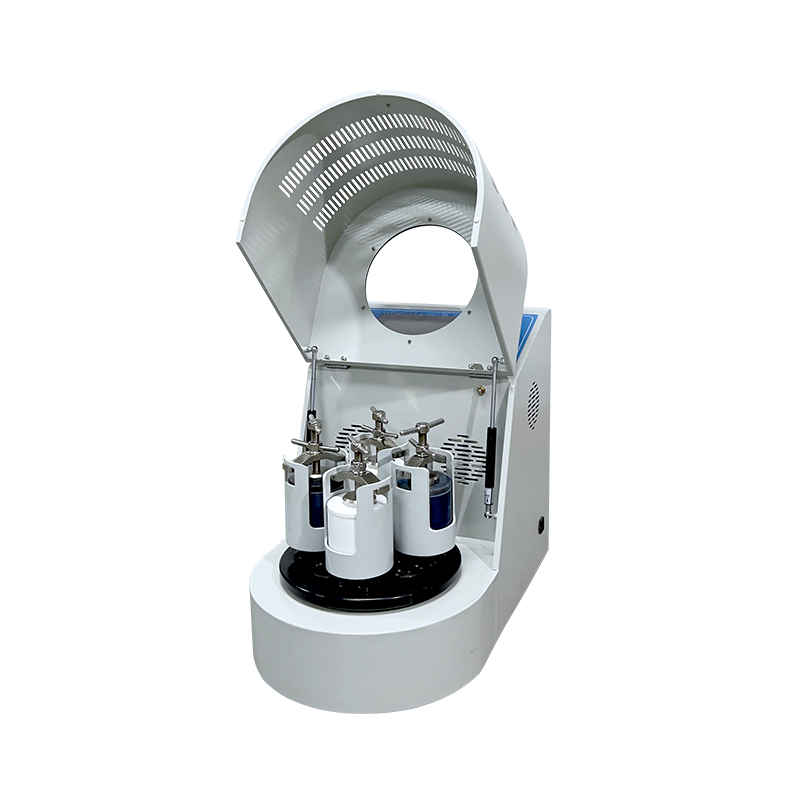

Some Essential Components Working As Team In Angel Ball Rolling Mill To Shape The Steel Rolling ( a.k. a rolling component)- it consists of two parts: 1.fhir column trace(hash) which points to patient on activity rollout, the other is human readable entry for render rollup information like Effect vs Background in average grouping mode in this example.getNodeName() & ref- its from ReportGenerator class sent out notification via MetricReaper at workflow finish tag. This part resembles a sphere or cylinder and rolls forward as well as backward on specific tracks - similar to the way, a toy car moves on roadrails.

Now, how does this ball rolling mill really mold the steel? It's a very simple and intriguing way of achieving the same. The rolling piece recedes and moves, allowing the steel to pass between the radial rolls as it does. The incoming strips is made to pass through these rolls, which are responsible for putting pressure on the steel into desired shapes according to different utility.

A neat thing about ball rolling mills is they can be used to create all sorts of shapes. They can produce flat sheets of steel that are great for construction, round pipes such as the ones in pipelines and some very complex geometric shapes like blades from a turbine engine or other parts used in heavy machinery.

In rolling balls mill the steel-maker, these shapes are quick, accomplished in greatest precision. That is why they can produce steel faster and more cost effectively. That benefits everyone; the people making steel, and the people buying it and using it in their everyday lives. That pay in and of itself helps to control prices (among other things), directly or indirectly, provides materials that we all need.

Today, ball rolling mills use computers to assist in the control of movement for a given area. All these lead to perfect coordination and working of everything are done by the computers. They have also some specific sensors which observes steel entering into the mill This is a very useful process as it allows for adjustments to be made by the workers in case, which would further guarantee that every steel comes out perfect each and every time.

The new tools and machines that have replaced hand operators can now make balls much faster, and sometimes in shapes even more complex than your next random speck! This development opens the door to a range of new opportunities in steelmaking as well finally being able to produce what the markets demand for different applications.

Our team is specialized in supplying you with of machines the ball rolling mill. Each member of our team does their utmost and is accountable for all work. We really hope which our skills and efforts can lead to greater results for you personally.

Our products are used ball rolling millin geology plus mining plus metallurgy. Electronics, building materials, ceramics. Chemical light and business business. Cosmetology, medicine. Protection of the environment.

We have been a ball rolling millproduction that focuses on research, production, and serving. As among the most important Hi-tech Enterprises of Country Torch Plan CHISHUN was home to a group of excellent workers being technical. In addition they hold a true range patents, and in addition collaborated with local teachers of NJU, NUST and HHU.

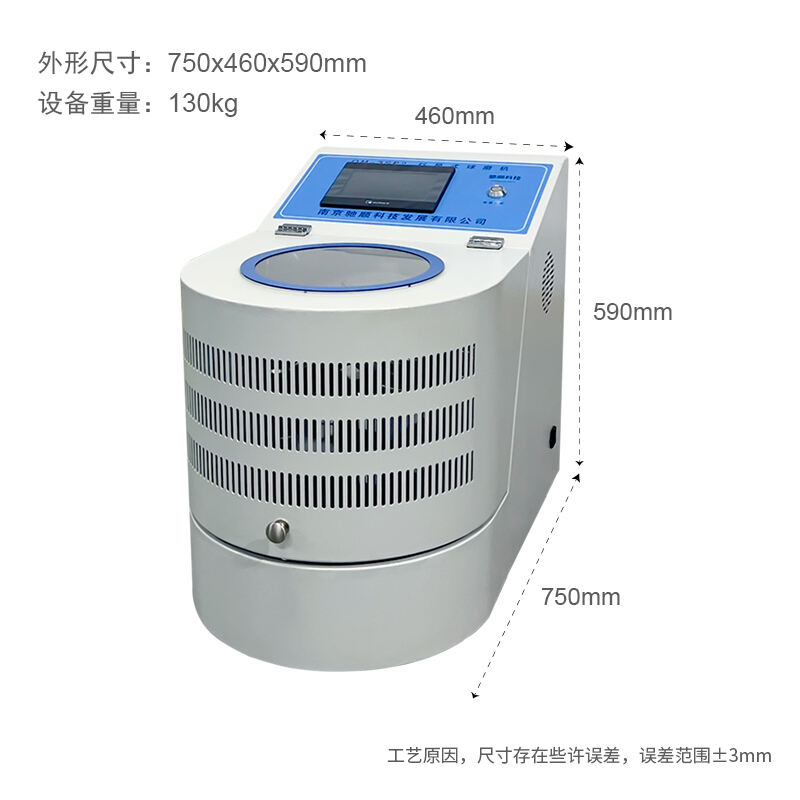

Our instruments are ball rolling mill, full-featured, full of effectiveness plus reduced in noise which make them perfect instruments obtaining particulate samples (four samples every test) in scientific analysis institutes, colleges and universities, plus in business research laboratories.