An example of a multifunctional type of size reduction energy device is a batch ball mill, which can mix, grind, and homogenize materials. The tool is advantageous in many ways and can find applications across industries. Below are some suggestions for improving the productivity and minimize the cost when having High-energy Planetary Ball Mill / PULVERIZER 500 / Four-jar installed.

Before discussing in what a batch ball mill can be used, we are first going to establish the difference between continuous grinding and batch grinding. It is a mill, round ball mill (not a mill with balls) It is a grinding mill that grinds and crushes. It is widely used in such industries as smelting, mining, quarries, and construction, waste treatment. The planetary ball mill is versatile and can be used for a wide range of disturbances.

One of the primary reasons why batch ball mills are so widely used, no matter the industry or material, is that they do a great job of milling things of different shapes and sizes. Whether you are grinding big lumps of raw materials or crushing small bits of raw materials, there’s a ball mill that is perfect as the solutions. This, in turn, makes it an essential reduction operation in a wide range of industries.

In addition to the size reduction of particles, batch ball mills can also be utilized to mix and homogenize materials. When substances are mixed together or made into a solution in a batch ball mill, the solids are crushed into a supple powder. That is an essential situation for a number industry who want to have uniform and steady materials for their course of.

Batch mill is also called intermittent ball mill/ceramic ball mill, intermittent operation of the dry and wet for the fine grinding of feldspar, quartz, clay, ore and other raw materials. Some of the most popular applications for the batch ball mill are in the mining, building materials and the chemical industry. In addition, they can be employed in food service and food processing applications to neutralize fat, mix and homogenize food product ingredients.

Another application of batch ball mills is in the chemical industry, where ball mill grinders are used to crush and grind materials like raw materials for cement and other chemicals. In general, batch ball mills are very suitable for the industries where a lot of grinding work need to be done, such as in small-scale production plant.

A few of the key concepts that you should remember if you are operating a ball mill in a batch configuration are :. First, the batch type ball mill must be kept in good maintenance by clean the machine properly and lubricating the machine well. This will eliminate any problems and the batch ball mill to part of the run don't have a big impact, it is to ensure the production of the premise of a good mill joint.

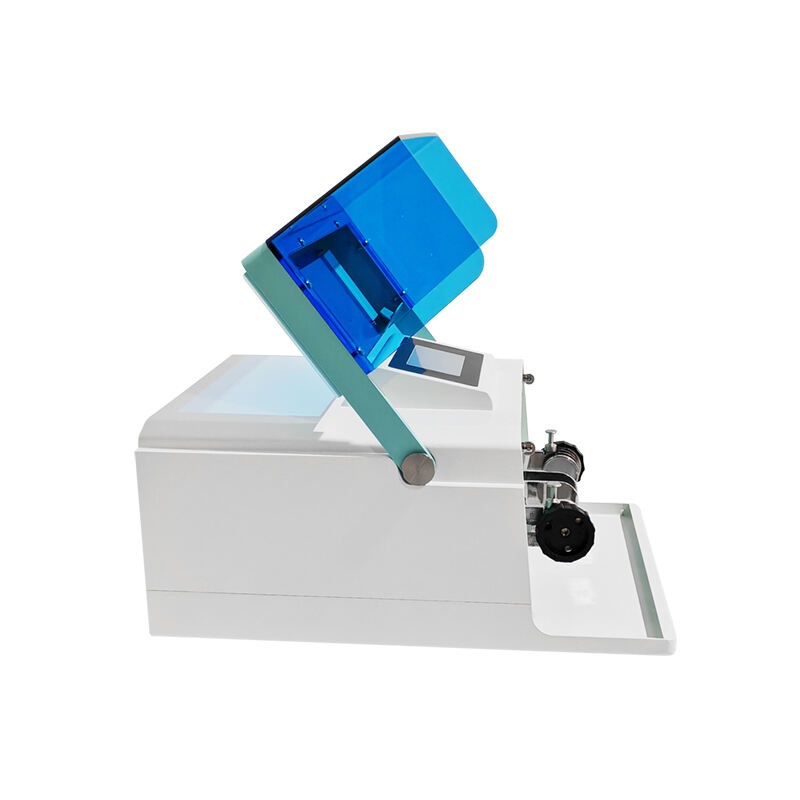

Our instruments are batch ball mill, full-featured, full of effectiveness plus reduced in noise which make them perfect instruments obtaining particulate samples (four samples every test) in scientific analysis institutes, colleges and universities, plus in business research laboratories.

we are specialized in providing you with machines for the batch ball mill. Each member of all of us works diligently and is accountable for the ongoing perform they do. We wish which our commitment and knowledge will allow you to create best work.

Our items are batch ball millfound in geology and mining and metallurgy. Electronics Building materials, ceramics. Chemical industry Light industry, chemical industry. Medicine, cosmetology. Environmental safeguards.

We have been a batch ball millmanufacturing that centers on research, production, and serving. The quantity of patents, along with working with local teachers of NJU, NUST plus HHU as one of the most important Hi-tech Enterprises of Country Torch Plan, CHISHUN possessed the most skilled technical personnel hold.