Box resistance furnaces are simply superb machines which serve the purpose of heating materials to extremely high temperatures. These instruments are mainly used in different factories and industries to manufacture a variety of products. Box resistance furnaces work with electric heating elements that produce extremely high heat upon which the material inside the furnace is then heated. These furnaces can be controlled in a fine way due to its design which gives the whole heating process unintermittant control.

Box resistance furnaces are changing the face of industrial heating processes and provide numerous benefits over conventional type of furnaces. Their main advantage is their incredibly fast & accurate heating capabilities with an insignificant amount of heat loss. Box resistance furnaces, on the other hand, have much better insulation compared to regular furnaces and retain heat in very effectively which makes them more energy efficient.

One of the important functions provided by box resistance furnaces is that they are able to improve both performance and accuracy in heating operations. These furnaces feature state-of-the-art computer systems that monitor and control the heating process with great precision. Such automation enables material to very quickly reach the required temperature, beyond what can be achieved manually with heating techniques. Another extremely important thing for the production of goods - is that it drastically simplifies maintaining a certain temperature in materials (for example with box resistance furnaces).

Box resistance furnaces are also used for industrial heating applications but they find application in material testing and heat treatment etc. Material testing means placing materials at different temperatures and conditions to observe their response which helps them, scientists and engineers understand the nature of your available material 2. On the other hand, heat treatment involves heating materials to strengthen or harden them typically used in machinery and metal components for manufacturing. With the controlled atmosphere feature of box resistance furnace material testing and heat treatment are made accurate with repeatable unmatched results.

While implementing a box resistance furnace for your business may enjoy extensive publicity in optimizing all other processes that need heating, proper cleaning routines and maintenance protocols have to be followed to maximize its benefits. To that end, the first step to furnace efficiency is following manufacturer guidelines for how to operate and take service of your unit. This may include things like routine maintenance such as cleaning the heating elements, maintaining temperature control or replacing any broken components. Second, be sure to schedule standard inspections by trained technicians who can keep the furnace operating at peak performance. Lastly, all safety procedures must be followed during operation of the furnace to prevent mishaps and maintain a safe working environment.

Thus, the advent of box resistance furnaces have significantly simplified industrial heating processes and ensured accuracy, speed as well as coherence in a wide range being heated among materials. Business Owners will need to gain a thorough knowledge of how these furnaces operate and the best practices for ensuring maximum benefit from having them installed in your business.

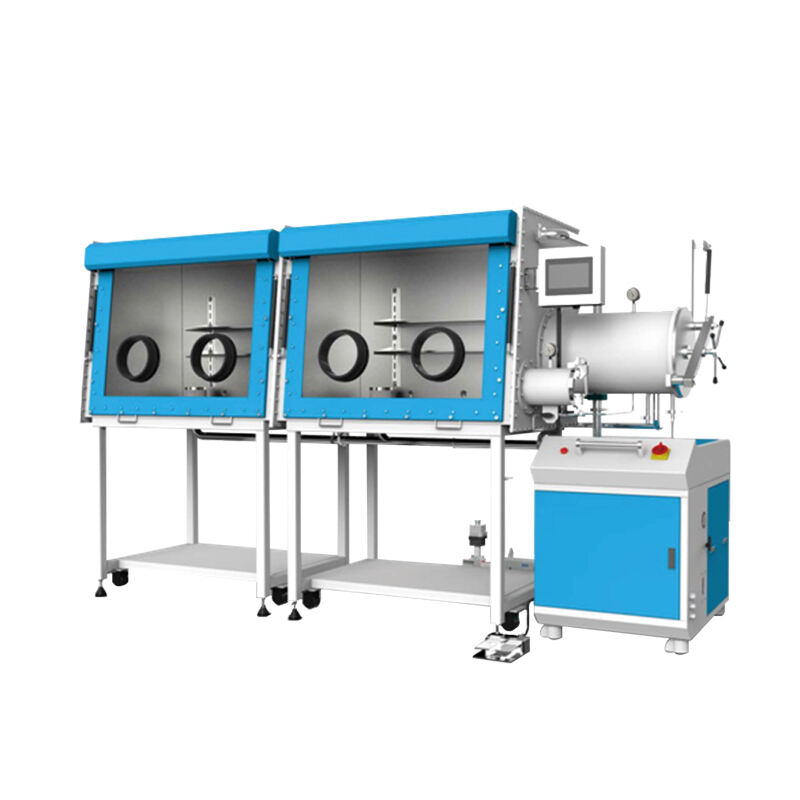

Our items are box resistance furnace, feature-rich, efficient, and silent. They may be perfect for capturing particles 4 samples for every experiment) in scientific research institutes and corporate laboratories.

We are a definite production is box resistance furnacethat blends research, production, purchases and service. Because one of many important Hi-tech Enterprises of Country Torch Plan CHISHUN gets the most skilled technical personnel and hold several patents. They as well as working and local teachers of NJU, NUST and HHU.

Our products are box resistance furnaceutilized in mining, geology metallurgy, electronics, building materials ceramics, chemical industry medical, light industry, cosmetology, environmental protection, etc.

Our team is dedicated to giving you machinery for the box resistance furnace. Every member of all of us does their best plus is responsible for the ongoing work they do. We sincerely wish that our skills and efforts will better work with you do perform.