High Integration of The Metal Sintering Furnace for The Production of Mechanical Parts

An exceptional machine that works wonders in the manufacturing of metal components, is the all popular - Metal Sintering Furnace. It allows the metal powders to be heated and melted, then fused together by cooling into a single solid metal component without any joints. Known as essentially a giant kiln that can be turned up to melt metal until it becomes almost liquid, the process is used in industries from aerospace and automotive to healthcare.

Metal sintering is the process of turning metal powders into hard metal parts at a quick pace. It is a complex process which need experienced operators to the operations of furnace. The method effectively melts and binds metal powders together by subjecting them to high temperatures and pressure inside the furnace, providing components a new level of precision in form accuracy. The resulting components have better strength and ductility, which makes them ideal for various industrial uses.

Among the various options of lines available, metal sintering furnace comes as top recommendation for industries eager to manufacture metal components. It has the ability to make parts faster than traditional forms of manufacturing Further, by made of metal powders is that complex shapes which was impossible to make use within the traditional methods can be obtained. Apart from optimized energy consumption in each and every step of the process, the furnace scores with top-class shaping accuracy which makes them ideal for applications that require tight tolerances.

The operation of metal sintering furnaces is fuelled by enormous amounts of energy that are used to bind the various metallic powders together and enable manufacturing components with high strength and durability. By offering this process in various metals (including stainless steel, titanium and aluminum), it allows an option to build with mix material spectrum line. Metal Sintering also is environmentally friendly as it reduces how much material goes to waste when produce compared to conventional production - a sustainable decision for businesses -.

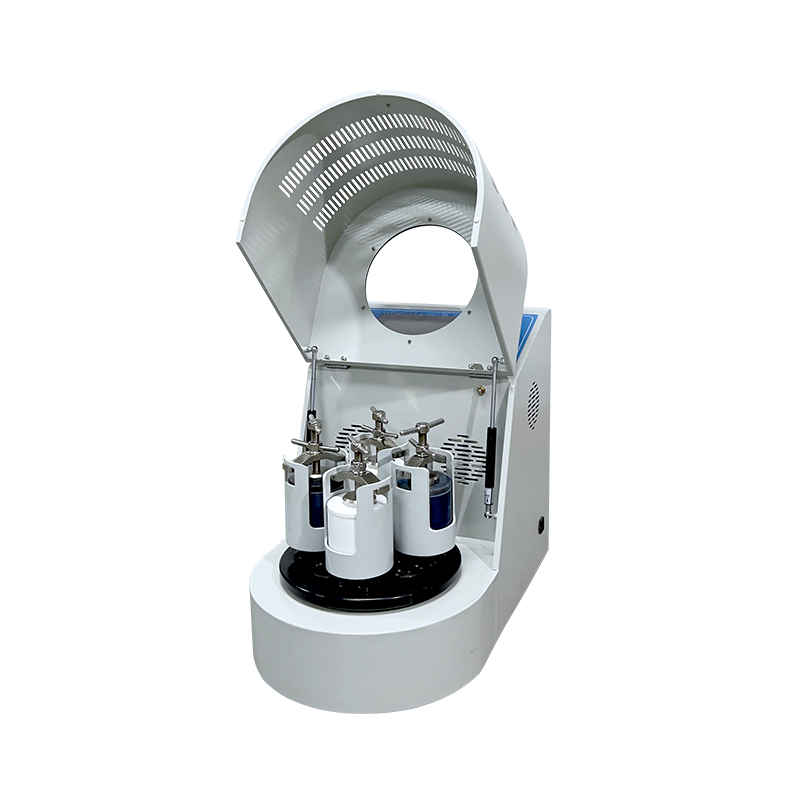

Features of metal sintering furnace - Companies in need to produce a large number of Metal parts at quick intervals can enormously benefit from the metallic Atmosphere Sintering Furnace. It outperforms traditional manufacturing by producing parts more efficiently, allowing businesses to keep up with stringent production timelines. In addition, because the furnace is capable of supplying complex-shaped parts directly it eliminates many processing steps that simplify manufacturing and improve overall efficiency.

In summary, the metal sintering furnace is a groundbreaking technology that can rapidly and easily convert metal powders into strong parts with excellent mechanical properties. Companies in the aerospace, as well as health industry could use this metal sintering furnace in order to simplify their manufacturing processes and construct superior precise parts. All in all, the sintering furnace for metal ranks among some of the most important tools being used in contemporary manufacturing; with its versatile design and powerful functionalities.

All of us is committed to provide you with metal sintering furnace equipment. Everyone on we does their utmost and is in charge of the ongoing work they are doing. Our company is certain that our expertise and effort will help you do better work.

Our items are utilized metal sintering furnacein geology plus mining, metallurgy. Electronic machines Building materials, ceramics. Chemical industry Light business, chemical industry. Cosmetology, medicine. Security for the environment.

Our instruments are metal sintering furnace, full-featured, full of effectiveness plus reduced in noise which make them perfect instruments obtaining particulate samples (four samples every test) in scientific analysis institutes, colleges and universities, plus in business research laboratories.

We have been a metal sintering furnaceproduction that focuses on research, production, and serving. As among the most important Hi-tech Enterprises of Country Torch Plan CHISHUN was home to a group of excellent workers being technical. In addition they hold a true range patents, and in addition collaborated with local teachers of NJU, NUST and HHU.