Vibration mills are very convenient machines, used to reduce the size of materials, by grinding these materials. They are high-energy grinding machines, which use a lot of energy in the process of making things smaller. It’s very efficient and time effective and can used in many industries. Let’s discuss how vibration mills work and the importance of this technology.

Vibration Grinder Machines A vibration mill applies the process of continuous impaction in carrying out its size reduction function. They operate by rapidly shaking a container filled with the material to be ground. The material is broken up by the levers vibrating against each other. This is a very efficient process and can be used to grind materials faster than can be done with alternate methods of grinding.

A great benefit of using a vibration mill is that the process is very efficient and labour-saving. As the materials are crushed through high energy vibrations, this process is quick, and quicker than other grinding procedures. It is for this reason that vibration mills are widely used for industrial grinders, which demand fast grind of large quantities of material.

The size reduction in vibration mill is no exception. When the materials are dumped into the container and the machine is started, the vibrations shake the material at each other. This impact causes the material to be broken down into smaller particles through a crushing mechanism. Vibration strength can be multiple adjusted to influence the result of the particles.

Vibration mills are widely used in such industries as food, chemicals, and mines. Vibration mills are used to crush pharmaceutical raw materials in the pharmaceuticals industry. These machines grind ores and other materials to extract minerals from them. Regardless of the surface type, the vibration mills are integral to the process of reducing the size.

Selection of a vibration mill considering the application When selecting a vibration mill for a specific application, several issues should be taken into account. First, the grain size and material of ground would determine the size and power of 3) the vibration mill to be used. The target particle size and high production capacity will also influence the choice of the vibration mill. And there is also the issue of maintenance, not to mention energy efficiency, all of which should be considered prior to purchasing a machine.

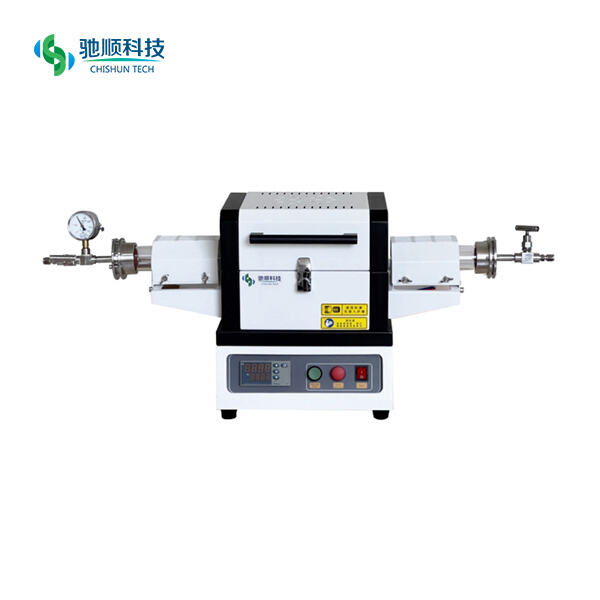

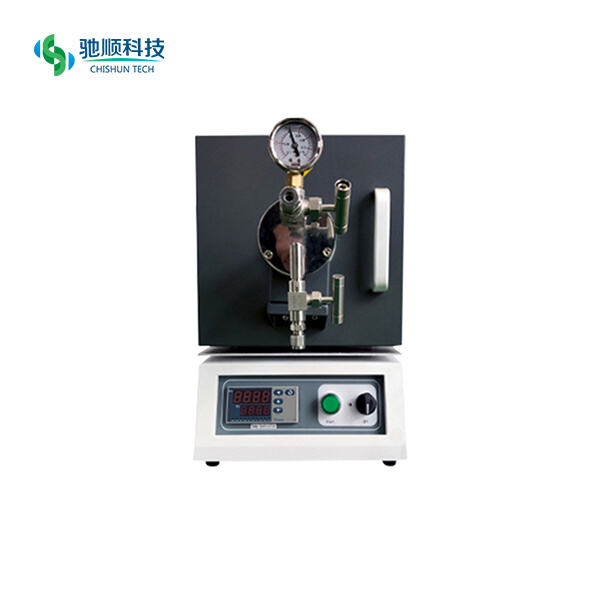

Our products is used vibration millin mining, geology metallurgy, electronics, building items chemicals, ceramics light industry, medicine, environmental protection, cosmetology, etc.

Our items are vibration mill, feature-rich, efficient, and silent. They may be perfect for capturing particles 4 samples for every experiment) in scientific research institutes and corporate laboratories.

We have been a vibration millmanufacturing that centers on research, production, and serving. The quantity of patents, along with working with local teachers of NJU, NUST plus HHU as one of the most important Hi-tech Enterprises of Country Torch Plan, CHISHUN possessed the most skilled technical personnel hold.

Our team try dedicated to supplying you with of apparatus the vibration mill. Each member of our team is faithfully accountable and dealing for virtually any little bit of work they do. We have been certain that our talents and efforts will bring you better work.