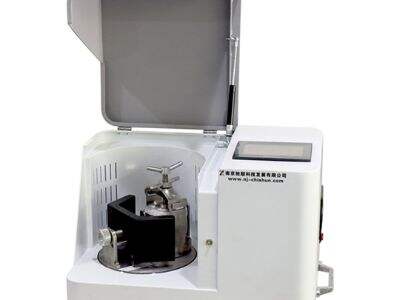

You may not realize it, but grinding small particles is something that happens all the time in our everyday lives. From our food to the drugs we take, little bits are everywhere. But how do we have pieces this small? This is the role of planetary ball mills.

A Lapping Machine For Grinding Ultra Small Features

Planetary ball mills are the special kind of machine used for grinding particles into smaller bits and they come in per milligrams (mg) or per grams (g). These mills rely on spinning to chew through crushed materials. They are employed in numerous industries — think medicine, beauty products and electronics — to make tiny particles of powder.

How Planetary Ball Mills Work

So how does a planetary ball mill work? Grinding balls are carried up by the rotating disc or bowl and accelerated to the point where they impact with an upwardly radiating roller. As the disc spins, the balls move and strike the material inside. This hitting produces large material crushing into tiny size.

Efficiently, Fast, and Accurate

One major benefit of planetary ball mill grinder is that they work very fast and very well. These machines can grind materials quickly, which is so efficient that it allows you to make more products more efficiently. They also make the particles all the same size.

Helping Different Industries

Planetary ball mills have altered our approach to particle size materialgrinding in regulation. For purposes of medicine, in medicine, they pulverize their ingredients into little bits for their better prescription. For beauty, they form fine powders for makeup. And in electronics, they help form tiny materials for devices.

A best practice to generate samples of small particles is to start with a a combined grinding and sieving (CGS) system, the raw material is first of grinding to generate a large surface of the cobalt particles.get price

The following are tips for achieving the best use of planetary ball mills. One trick is to pick the appropriate size and number of grinding balls and the material you want to crush. It’s also essential to manage speed and duration to achieve the same results, every time you grind. Maintenance for the machine is important to keep it operating at its best.

Finally, ball mill grinding machine are widely used for grinding particles under the size of dry grinding. They're great for fine powders with all the accuracy and speed. Using the latest mills depending on best practice design, these mills reduce delivering effectiveness technology.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH