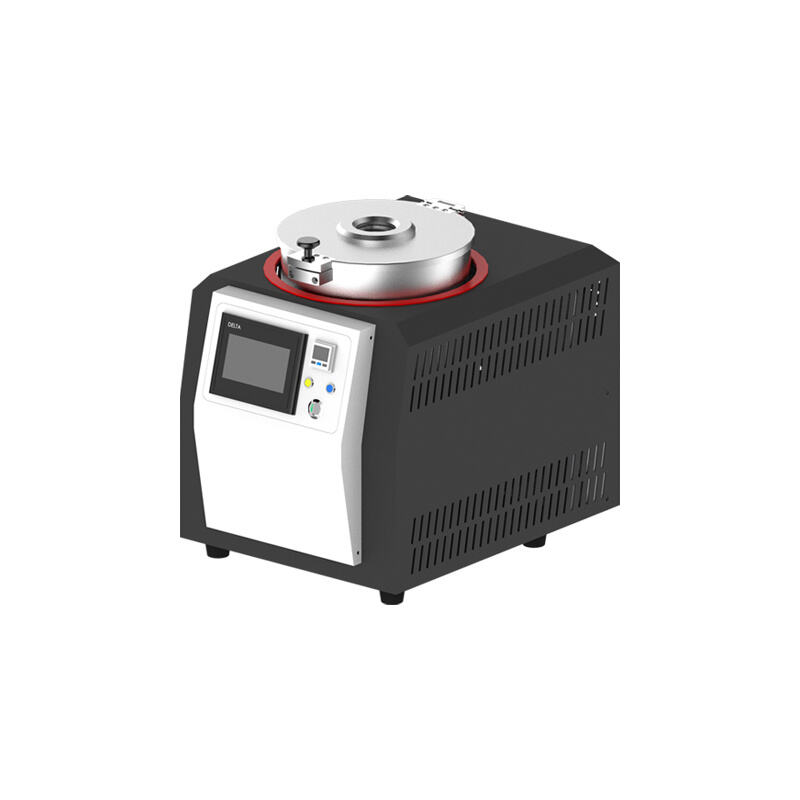

Devices like vacuum glove box systems are indispensable when you are dealing with materials that need to be processed away from oxygen and humidity. These systems then form a special seal and use vacuum to take air out and fill with inert gases such as nitrogen or argon. This prevents negative reactions that can ruin delicate goods. People who use vacuum glove boxes can work on sensitive procedures like electronics, chemicals or medicines production without having to expose things to air. Nanjing Chishun makes these machines so that industries can protect their products from impurities and ensure they won’t break down. The design allows operators to put their hands inside the box with gloves attached, so nothing from outside could get in and nothing inside could get out. It’s not only an implement but a shield, defending the work and assuring a better outcome.

The Importance of Vacuum Glove Box Systems in Creating Inert Atmosphere Conditions

To maintain an inert atmosphere inside a glove box is not child play. If the smallest hole or crack appears, it will allow air or moisture to dribble in and spoil the atmosphere that sensitive stuff must have. Nanjing Chishun’s vacuum glove box systems are designed to create and maintain that unique environment through a complete removal of air and filling in the insulated box with an inert gas. The vacuum component first pulls out oxygen and moisture, so environment is very clean before any work begins. Then the inert gas takes up the space, preventing any chemical reactions that might occur due to the presence of oxygen or humidity. Think of trying to bake a cake without letting any air into the oven only with obstacles everywhere (it’s far more difficult because air and moisture are omnipresent). They dead-end at the vacuum glove box. At times, the process inside must be repeated many times to ensure that the environment remains as pure as it can be. The system is set up with sensors and controls that monitor the atmosphere constantly. If there is too much oxygen, the system warns users or automatically refreshes the gas. Nanjing Chishun proves what a massive difference good sealing, powerful vacuum pumps and intelligent gas control can make. It guards work against contamination, while protecting workers from toxic fumes and dust. Without them, keeping the environment stable enough to do high-quality work would be nearly impossible. Even tiny amounts of oxygen can be damaging, so the vacuum glove box is a necessity for many industries.

Enhancing Product Quality During Processing in Inert Atmospheres with a Vacuum Glove Box System

But it’s not only about keeping air out; vacuum glove box systems actually help make products better. Chemicals can’t react with oxygen or moisture when materials are manipulated in a pure inert atmosphere, so their chemical and physical properties remain very much the same. For instance, some metals can easily rust if they come into contact with the air, and certain chemicals can degrade and lose their potency. Nanjing Chishun’s vacuum glove boxes prevent this from occurring. Products emerge stronger, more reliable and last longer. That’s especially important to industries like electronics, where small impurities can lead to devices failing. It also puts less waste in the atmosphere, as fewer batches have to be tossed due to contamination. And the glove box also permits workers to manipulate materials without directly handling them, thereby avoiding human error. This system can also accommodate such precise tasks as mixing chemicals or assembling parts, which can be ruined by even a small misstep on the part of the user. Many customers find that their yield goes up after they begin using vacuum glove boxes, the amount of good product increases and defects cost less. It’s not magic or mystery that the redoubtable Nanjing Chishun delivers to Australian clients but exquisite design, management and attention to details. The feeling of relief that the work is protected and taken care off, is soothing to operators. The quality is not only higher; it’s more consistent, and that has proved invaluable to manufacturers that hope to compete.

Why are Vacuum Glove Box Systems the Best Option for Handling Sensitive Materials

When using a material that is extremely sensitive to air, moisture or dust, the material must also have a special place where they can be isolated from such conditions. Put to the test Vacuum glove box systems are ideal for this task, since they can provide a safe and clean environment in which sensitive materials can be handled without fear of damage. These systems evacuate air and other unwanted gases from the inside of the box, replacing them with an inert gas, like nitrogen or argon, which doesn’t react with the materials. This is referred to as processing under an inert atmosphere.

Nanjing Chishun’s vacuum glove boxes are engineered to maintain extremely pure internal atmosphere. By extracting oxygen and moisture, the system freezes materials in time to prevent them from changing or degrading. This is critical in industries such as chemistry, electronics and pharmaceuticals, where even a small amount of air or water can ruin a product or an experiment. The attached box gloves enable workers to manipulate materials safely without opening the box, keeping the clean environment intact.

Another cause that tends to make vacuum glove box systems a terrific option is the fact that they allow workers to view and manipulate smaller or delicate objects with out possessing to remove them in the handle cabinet. The walls of the box are clear and there is good light, and the gloves are designed to be comfortable and allow accurate movement. This also helps ensure that even small or fragile items can be treated with all due care in order to avoid accidents or breakages.

To sum up, such Nanjing Chishun’s vacuum purification glove box system are suitable for handling of sensitive materials as they facilitates a special atmosphere devoid of moisture and air. This protects materials, allows fine work and produces better results in dozens of important fields.

What Are The Salient Features Of High Quality Vacuum Glove Box Systems For Inert Atmosphere Processing?

Features of vacuum glove box systems Some features make high-end vacuum glove box systems convenient and reliable for working under an inert atmosphere. Nanjing Chishun engineers these critical elements into its systems to ensure that users get the most and best results first hand.

Airtight sealing of the glove box is one of the main characteristics. That is, once the box has been sealed and filled with inert gas, no air or moisture can get in. The seals are constructed from durable materials and will not break down as quickly, keeping the box clean and safe for an extended period. This is because a leak can introduce oxygen or water, both of which might ruin the delicate materials that are housed within.

Another salient feature is the vacuum control. Nanjing Chishun vacuum glove box system, featuring user friendly controls that give a high level of control over the air and moisture content before adding inert gases to fill the chamber. This control system also maintains a stable pressure within the box to keep the environment safe for delicate work. Good pressure control also means the gloves won’t end up too hard or too soft to use, and workers can do their tasks more comfortably.

The gloves themselves are another crucial piece. They’re durable, pliable and fit snugly on the user’s hands. These allow workers to wriggle their fingers into the box, and so handle fragile articles carefully. This is lined and gloves are adhered to the box tightly enough so that nothing leaks out and kept the clean environment sealed in.

Furthermore, quite a few of Nanjing Chishun's premium systems come with see-through panels constructed from specialty glass or plastic. These screens are scratch-resistant and let bright light in so users can see clearly while working. Some of the boxes also include built-in lighting to make them even easier to see.

Last but not least, some of glove boxes have bonus features, such as gas purifiers that keep the inert atmosphere great for a long time without frequent changes. This in turn saves a great deal of time and money, and generally makes the process much more efficient.

In conclusion, a high-quality vacuum glove boxes for the Nanjing Chishun should have features such as air tight seals, ease of vacuum and pressure control, comfortable gloves, clear view panels; and occasionally they may come with gas purifiers. Together, these features provide the optimal setup for inert atmosphere applications.

Vacuum Glove Box Systems for Safer and More Efficient Chemical and Pharmaceutical Processing

Efficiency and safety are crucial when dealing with chemicals and drugs. Many chemicals are hazardous if they come into contact with air or moisture, and some drugs must be produced under extremely clean conditions. Glove Box Systems, Nanjing Chishun, creates a controlled environment in which a worker can operate without fear from the hazardous materials used to set-up before and clean down after a process.

One way that these systems promote safety is by shielding workers from harmful agents. The glove box serves as a shield, preventing harmful chemicals from wafting out into the air. This ensures the workplace is safe and minimises any accidents or health issues. The sealed environment also prevents fires or explosions, which can occur when certain chemicals react with oxygen.

Meanwhile, the vacuum and the inert conditions in the interior of the glove box offer a safe environment for processed materials. That means that chemicals do not degrade or alter, and medicines may be produced more pure. Application of the glove box systems provided by Nanjing Chishun can be sure to meet very high quality requirements, and this is crucial in pharmaceuticals.

Productivity is also higher as workers can perform their tasks without taking a break. Because the environment inside remains consistent, workers don’t have to stop and repair issues caused by air or moisture. Simple control panels and clear viewing panels help workers work more quickly and accurately. This makes for efficient preparation and less waste, helping companies control costs.

Furthermore, these glove boxes are generally equipped with characteristics that make easy work of cleaning and maintaining them. Quick and easy upkeep translates to fewer downtime, meaning workers can spend more time on enhancing output. Nanjing Chishun makes its systems easy for operators, so companies can focus on getting business done.

Nanjing Chishun valve regulated glove box systems provide 3 clear advantages safety for humans and materials, efficiency in creating a stable easy to work in environment. This makes them indispensable instruments for chemical and pharmacy of handling.

Table of Contents

- The Importance of Vacuum Glove Box Systems in Creating Inert Atmosphere Conditions

- Enhancing Product Quality During Processing in Inert Atmospheres with a Vacuum Glove Box System

- Why are Vacuum Glove Box Systems the Best Option for Handling Sensitive Materials

- What Are The Salient Features Of High Quality Vacuum Glove Box Systems For Inert Atmosphere Processing?

- Vacuum Glove Box Systems for Safer and More Efficient Chemical and Pharmaceutical Processing

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH