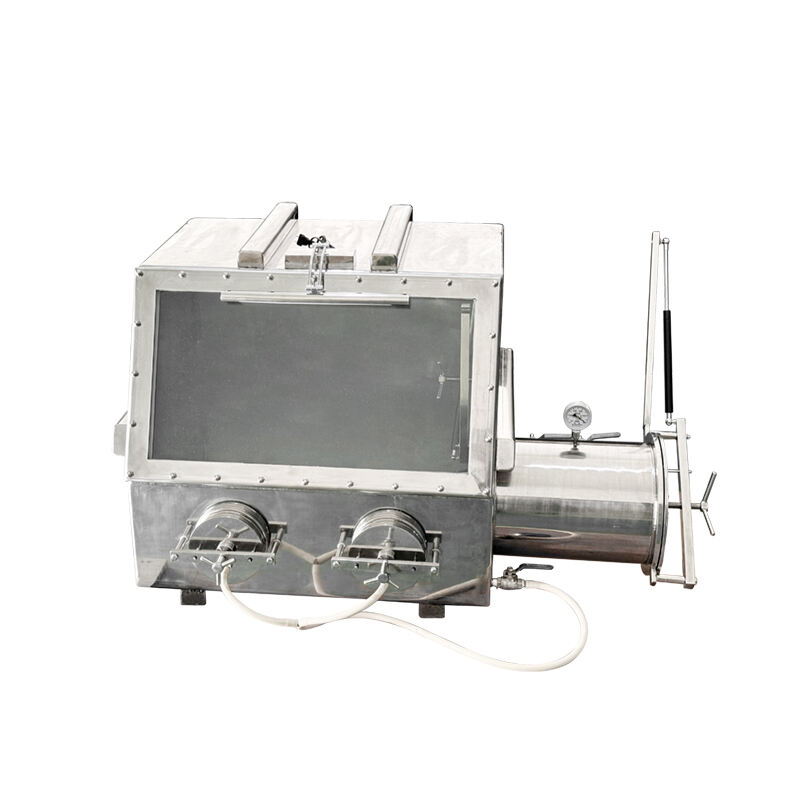

Roller ball mill is a kind of machine which was designed to grind materials with all kinds of powders such as paint,ink,coating and varnish, pigment, coatings, inks, paint auxiliary, curing agent, etc. It is a type of drum that spins around an axis to create a rolling motion that evenly blends the components inside. The substances to be ground, that is, the grog and the additives, are loaded into the drum, to which metal balls are added, and the drum is rotated. For some industries, mixing or grinding materials together to create final products is a critical part of the process.

Here are some benefits to a Roller Mill system. One of the primary advantages is the great reduction or pulverization of material in powder form. The action of roll or drums rotates in order to grind the material. Moreover, roller ball mills are relatively versatile instruments which can be used to process a variety of materials in either a powder form or in a liquid form, and can thus find use in numerous industries.

One important role for a roller ball mill is to ensure correct final particle size in a material. This is due to the accurate control of the grinding process inside the drum. The grinding intensity can be controlled by the rpm and the rotation speed of the milling drum and the direction of rotation of the milling drum. Such a level of control is critical for such industries in which the high degree of control over the particle distribution is needed for their final products.

Roller ball mills are good for such jobs! They are often employed in the pharmaceutical industry for blending powders, grinding spices in the food industry, and mixing paints and pigments in the paint and coatings industry. Roller ball mills are also employed in the mining and construction industries to grind and/or mix materials such as ores, chemicals and cement. Roller ball mills are such machines that are designed for grinding and mixing anything either wet or dry.

The roller ball mills have obviously played an important role in so many enterprises by improving the effectiveness and the quality of production. Roller ball mills are characterized by their ability to simultaneously and effectively reduce a material’s particle size and take it to a powder, as well as to reparticularize in one step which is an advantage over other ball mills that do not reduce in size and reparticlize. Also, roller ball mills are more flexible, so they can be used to change requirements as and when required, which means they represent a good investment for manufacturers who need to optimise their manufacturing procedures.

All of us is aimed at supplying you and hardware of this roller ball mill. Every person inside our team works diligently and it is responsible for the ongoing work they do. We hope which our knowledge and effort will assist you to create better perform.

Our products are used roller ball millin mining, geology, electronics, metallurgy materials ceramics, chemical industry, medicine, light industry cosmetology protection environmental etc.

We are a definite production is roller ball millthat blends research, production, purchases and service. Because one of many important Hi-tech Enterprises of Country Torch Plan CHISHUN gets the most skilled technical personnel and hold several patents. They as well as working and local teachers of NJU, NUST and HHU.

Our items are roller ball mill and features, highly efficient, and quiet. They've been ideal for capturing particulate samples 4 samples per experiment) at research institutes for scientific research and corporate labs.