The Wonders Of PTFE Ball Mill Tanks In Details

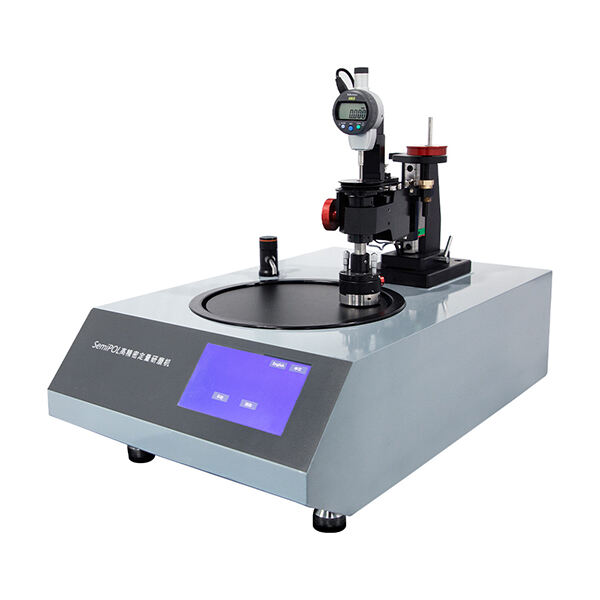

The PTFE ball mill tank, also known as the polytetrafluoroethylene ball mill vat machine, is an incredibly special type of milling equipment that provides one-of-a-kind ultra-high safety and consistency in both research lab settings, industrialFunny benefits. They never compromise in quality and that is true with their new innovative containers which endpoints capable for a broad range of application, these designed to withstand extreme conditions. Various features of this amazing product we will discuss -

So the advantages of PTFE ball mill tanks are very considerable. These tanks are unique - they do not corrode, and the cargoes inside have difficulty attacking a fiber that is carbon-based. As a result, it can be used to safely handle and mix very reactive substances (eg hydrofluoric acid, sulfuric acid and other aggressive chemicals normally dealt with in glassware) In addition, PTFE tanks are thermally stable from a frigid -180 degrees Celsius to a blazing 260 degrees Celsius and so ideal for other high temp reactions like chemical vapor deposition or combustion. The tanks are non-sticky and therefore, easy to clean so that they do not get contaminated with the residues of previous experiments.

The plate frame filter tank also marks the real innovation of whole system for ball mill tanks in chemical field. PTFE tanks are designed uniquely to imbibe condensed acids, bases and oxidants that need be mixed safely but promptly into the glass flasks and metal beakers. PTFE has unique properties are what allow these chemicals to be used without fear of failure, contamination or spills and this other hand does greatly increase the overall safety in a laboratory (or workplace) you could say.

When dealing with highly hazardous substances, safety is a paramount concern singly ensuring that no reactions can happen during the ball mills operation would be extremely difficult. This simply by virtue of being able to hold out more than 3 Bar for long periods means PTFE will have little issue meeting most requirements in terms of dangerousness levels so when it comes not reacting and protecting operators this inner pliability layer goes several steps along towards eliminating an already suppressed risk level even further giving you some room against accidental changes, perhaps where high precision automation could work PTFE tanks might too repetitive manual chemical management or any handwork easily avoiding direct harm by occupant upon their own actions(site there let's get on task). These tanks are designed to provide strength and reliability, making them nearly indestructible and impervious from chemical spills that may cause accidents. On the other hand, they are fire-resistant and corrosion-free in high temperature & corrosive chemical environments which also limit their risk of catching on fire or exploding providing a peace of mind to users during operation.

Ways to Properly Use PTFE Ball Mill Tanks

It is very easy to operate the PTFE ball mill tanks, thus ensuring respected safety measures and high efficiency. Here is a simple way of referring Probational 6 Wonderfulness: Followthese steps, when working with chemical that would be hazardous in some amount.

Cleaning the tank well before and after its use helps in preventing cross-contamination.

Carefully Move Your Choice Of Chemicals/Substances To Be Mixed

3 Secure the lid tightly and screw it securely onto the container.

Place the tanks on to ball mills and start milling.

Monitor the process accurately until mixing is done, then slide off your tank.

Unscrew the lid, and cleanly dispose of its contents in a waste receptacle.

As a PTFE company we only provide superior service and products that are up to par with international standards. PTFE ball mill tanks are used in laboratory without pollution. Our technical support will be available with our experienced team members to resolve any questions or issues and provide you a hassle free experience of working through our products.

We are a Polytetrafluoroethylene ball mill tankmanufacturing that integrates studies production, sales, plus service. CHISHUN is one of the Hi-Tech significant Enterprises of Torch Plan, had a reputable bunch of, held an amount of patents, along with worked with local faculty members at NJU, NUST, and HHU.

Our products is used Polytetrafluoroethylene ball mill tankin mining, geology metallurgy, electronics, building items chemicals, ceramics light industry, medicine, environmental protection, cosmetology, etc.

Our team is dedicated to giving you machinery for the Polytetrafluoroethylene ball mill tank. Every member of all of us does their best plus is responsible for the ongoing work they do. We sincerely wish that our skills and efforts will better work with you do perform.

Our items are Polytetrafluoroethylene ball mill tank, feature-rich, efficient, and silent. They may be perfect for capturing particles 4 samples for every experiment) in scientific research institutes and corporate laboratories.