Πλανητικός άνθρακας μπάλας / Εργαστηριακού τύπου / 04L

- Επισκόπηση

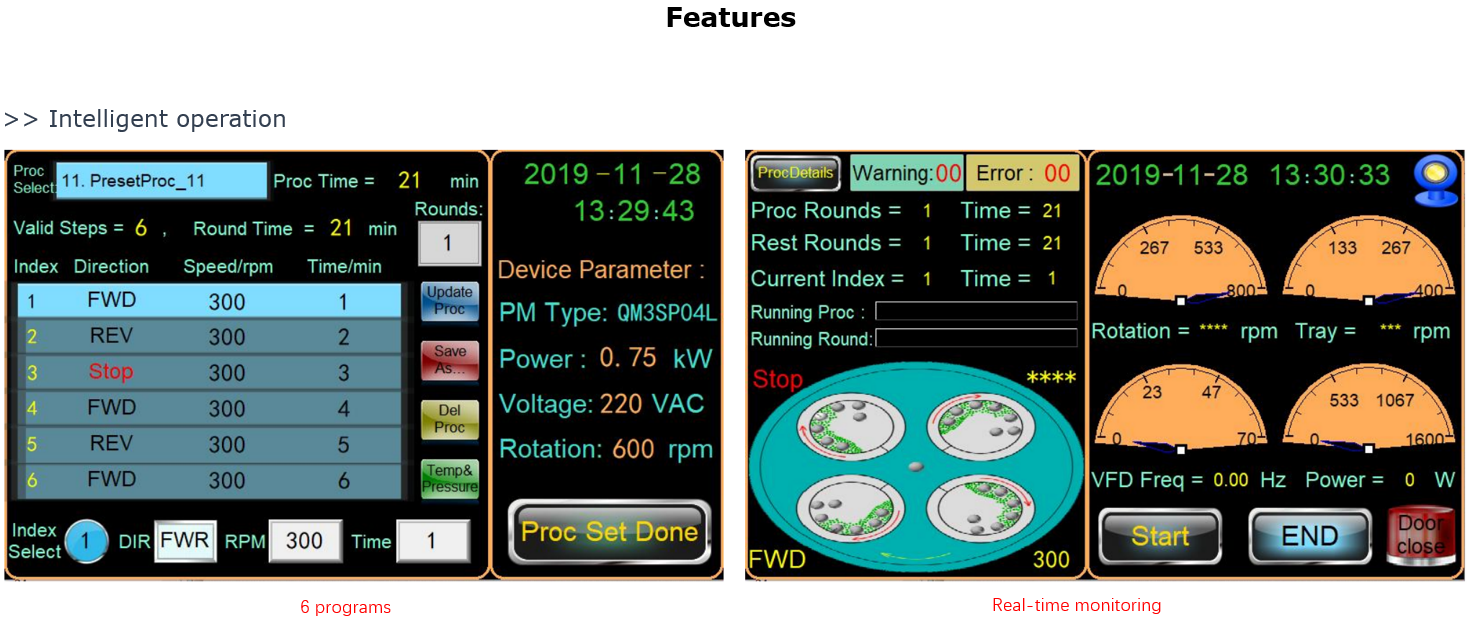

- Χαρακτηριστικά

- Τεχνική προδιαγραφή

- Βίντεο

- Ερώτηση

- Σχετικά Προϊόντα

|

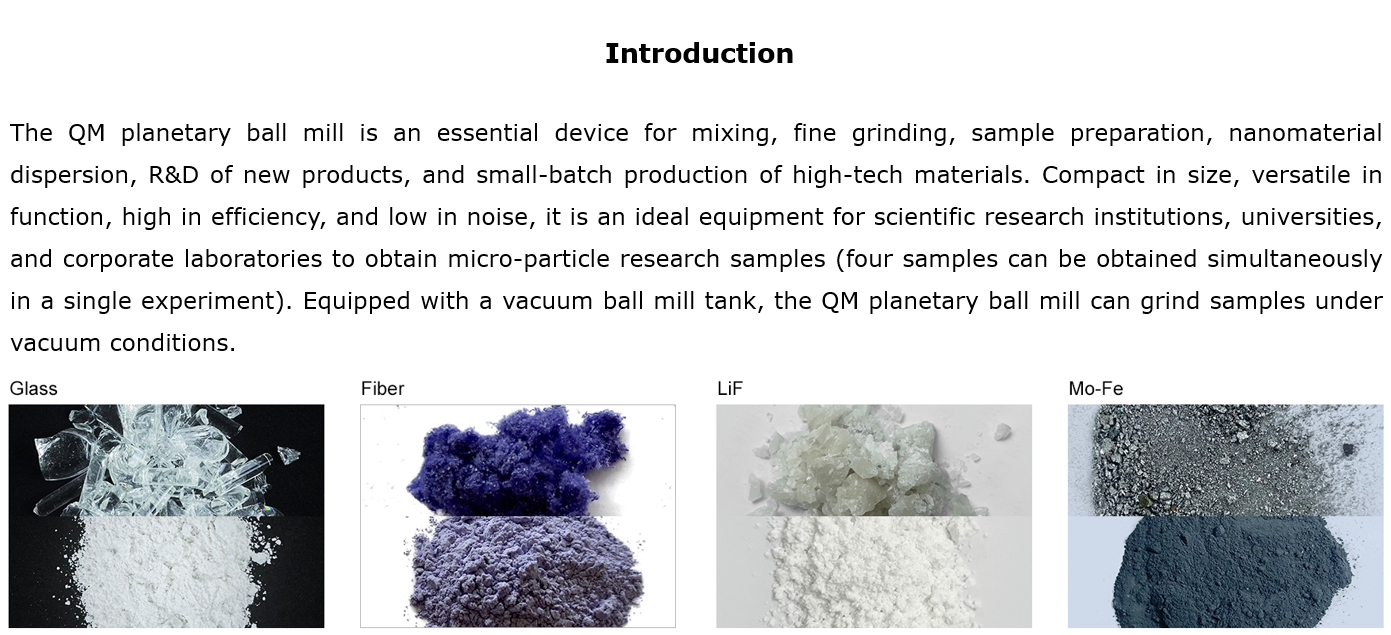

Εφαρμογές: |

Ηλεκτρονικά υλικά, γη, αεροδιάστημα υλικά, μπαταρίες, κεραμική, μετάλλια, μεταλλουργία, κλπ. |

|

Εφαρμοστέα δείγματα: |

Μαλακά, σκληρά, τραχύ, ινωδές, ξηρά ή υγρά |

|

Μέγιστος όγκος εισαγωγής: |

2/3 του μαλακιστικού κανάδιου |

|

Κενού μαλάκισμα: |

επιλογικό |

|

Μέγεθος εισαγωγής: |

γη ≤10mm άλλο ≤3mm |

|

Τελική λεπτότητα: |

0,1μ m |

|

Εναλλακτική χρονοδιάγραμμα: |

1-9999λεπτά |

|

Εναλλακτική |

800rpm |

|

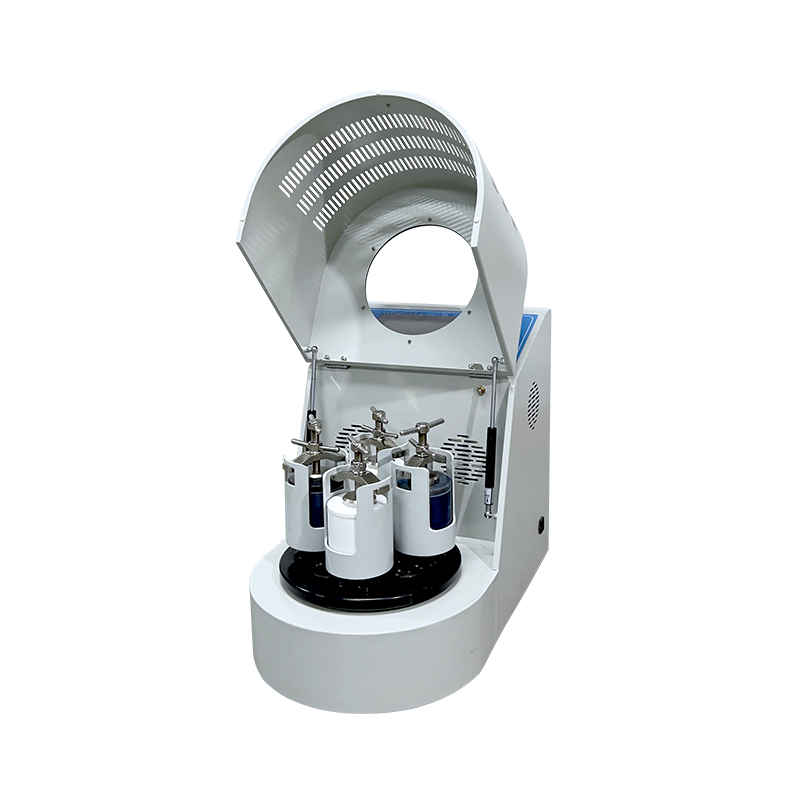

Κανούνι βρασμού: |

50ml, 100ml |

|

Κανούνι κενού: |

50 ml |

|

Πιστοποιητικό: |

UL, CE |

|

Δύναμη: |

220V 0.75kw 50~60Hz |

|

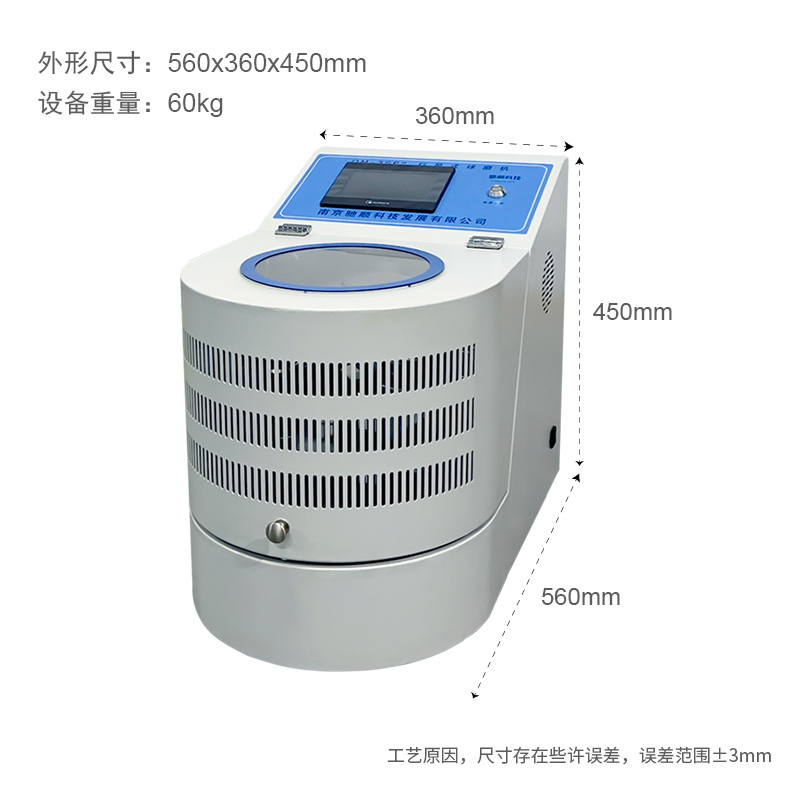

Διαστάσεις: |

56*36*45cm 60kg |

|

Αποθήκευση δεδομένων: |

120 σύνολα διαδικασιών |

|

Παρακολούθηση δεδομένων: |

Παρακολούθηση σε πραγματικό χρόνο της κατάστασης λειτουργίας, με υποστήριξη ειδοποιήσεων σφαλμάτων |

|

Προγραμματιζόμενη λειτουργία: |

6 σύνολα βημάτων λειτουργίας με υποστήριξη επεξεργασίας/διαγραφής |

|

Τρόπος ελέγχου: |

οθόνη αφής HMI 7", Πολλαπλές λειτουργίες λειτουργίας (λειτουργία προς τα εμπρός και προς τα πίσω εναλλάξ, λειτουργία με διαστήματα, λειτουργία με χρονοδιακόπτη) |

|

Υλικά για τα κουτιά: |

Ανοξείδωτος χάλυβας, κενό, αχατης, ζιρκονία, αλουμίνα, PTFE, νάιλον, βολφράμιο καρβίδιο κ.ά. . |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH