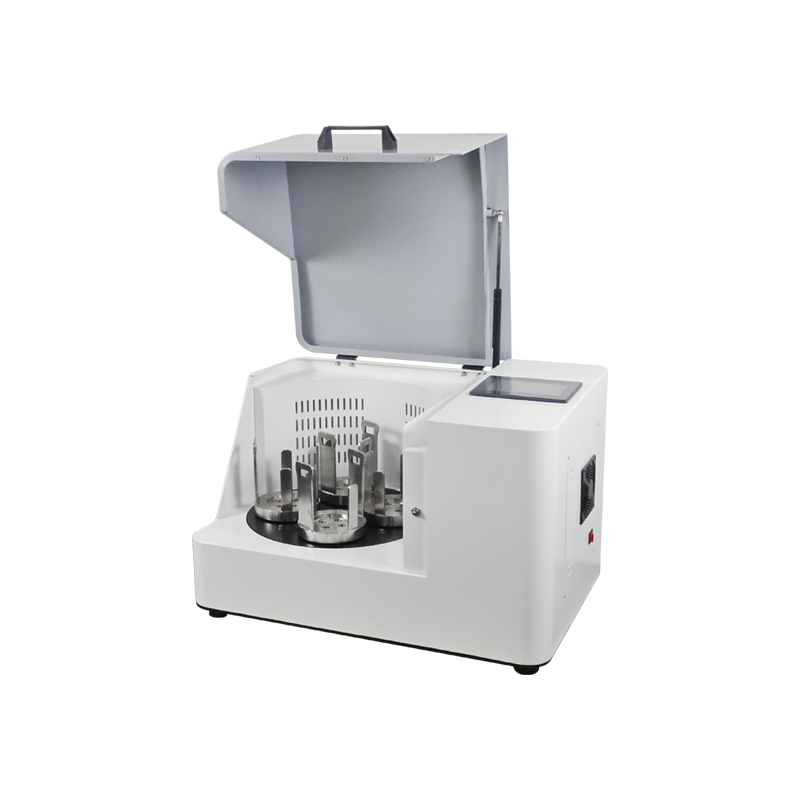

Exploring the Ball Mill Mixer

Have you ever tossed marbles about letting them twirled through your fingers and slipped quickly from hand, covering distance of whole hall? The ball mill mixer enables not only to crush those marbles into a fine powder. In this article, we will take a closer look at ball mill mixer and understand why they are important tool used for various applications.

Advantages

Advantages of using a ball mill mixer One factor attributable to improve the Melium is for grinding materials can convert material from large size such as rocks and lumps into minor particles. In the case of semiconductors, precision is important for electronic materials and samples may need to be uniformly sized or distributed across a surface. In addition, the ball mill mixer is considerably efficient and can process a lot of materials in one time. Moreover, its flexibility enables the handling of various materials like chemicals, minerals and food products.

One of the most characteristic features of Ball Mill Mixer is it will able to actually grind material together while mixing. The machine allows the materials to mix uniformly and homogeneously by smoothly blending/ grinding it during operation. This breakthrough ends the requirements for separate mixing and grinding machines, freeing up time and space in material processing.

When you work with a machine, safety is the top priority and ball mill mixer comes equipped with multiple built-in safety features to save you from potential harm or accidents. For example safety guards are installed in the machine, to avoid any touch with vital mechanical parts of the devices. In addition, it has an installed emergency stop button to immediately shut down the machine if needed. This, along with the built of high-quality materials contributes to its maintained service and more reliable operation which limits failures or accidents.

Our Ball Mill Mixer had very sophisticated features and is easier to be handled even by unskilled person. The machine is easy to operate, merely feed the material into drum and start the grinding,mixing process. If tweaks to the speed or other variables are needed, the controls of this machine were quite simple and easy find.

How to Use

To help you understand the process, we are sharing some of the steps involved in using a ball mill mixer.

If your material is dry just so you can fire up the candle closest to camphre and any debris that may be harmful.

Put the fabric in to the drum of your machine.

Turn on the machine and control speed.

Let the machine grind and mix it for as much we need.

Stop the machine and slowly take out the already processed material from inside drum.

If you have any questions or concerns with your ball mill mixer, the company can act on short notice in order to offer help. Their team of professionals is here to make sure your machine operates smoothly, regardless if you need technical assistance, or operational advice. Many businesses also provide periodic servicing and repair solutions to be certain that the machine operates properly.

Our instruments are Ball mill mixer, yet feature-rich, full of efficiency and quiet, making them suitable for getting particulate samples (four examples within one test) at scientific research institutes, universities and colleges, and corporate research.

Our goods are employed Ball mill mixerin geology, mining, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, cosmetology, environmental protection etc.

we are specialized in providing you with machines for the Ball mill mixer. Each member of all of us works diligently and is accountable for the ongoing perform they do. We wish which our commitment and knowledge will allow you to create best work.

We are a Ball mill mixermanufacturing that integrates research, production, sales and services. Being 1 of the key Hi-tech Enterprises of Country Torch Plan CHISHUN was in fact home to an excellent group of personnel and hold many patents. in addition to dealing with local teachers of NJU, NUST and HHU.