Ceramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness. They are used in industries from mining to construction and ceramics. Nanjing Chishun Technology Co., Ltd is a China-based Manufacturer of ceramic ball mills. We discuss the benefits of using a ceramic ball mill during the grinding process, how a ceramic ball mill can improve efficiency in materials processing, features and production technology of ceramic ball mill, maintenance considerations for ceramic ball mills, and a comparison of ceramic ball mills with cast iron ball mill.

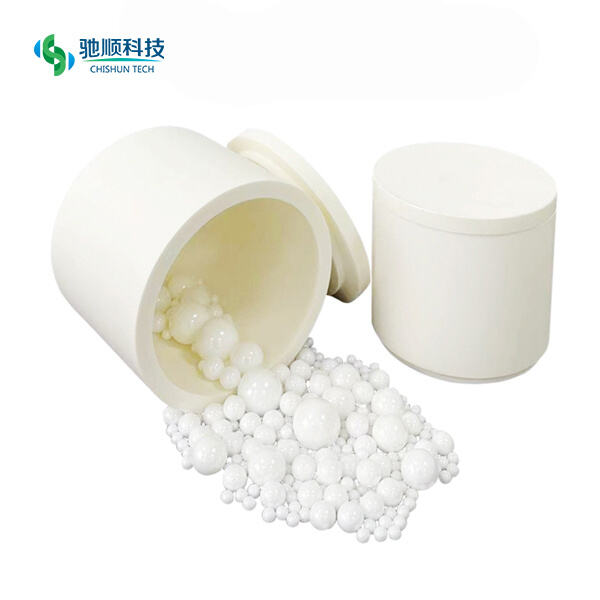

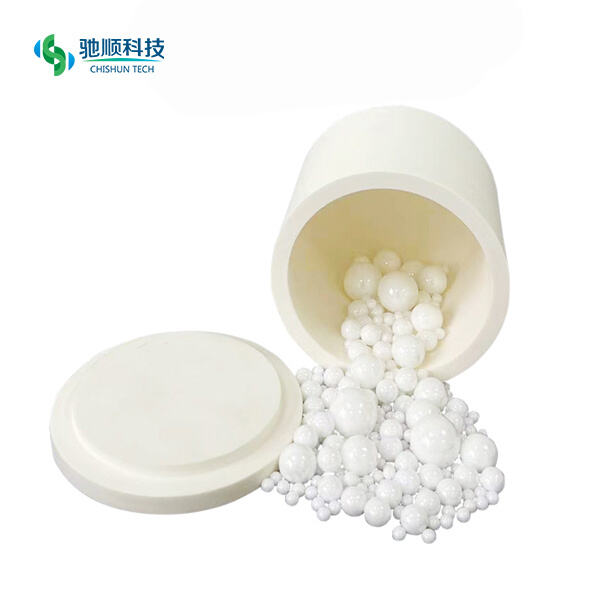

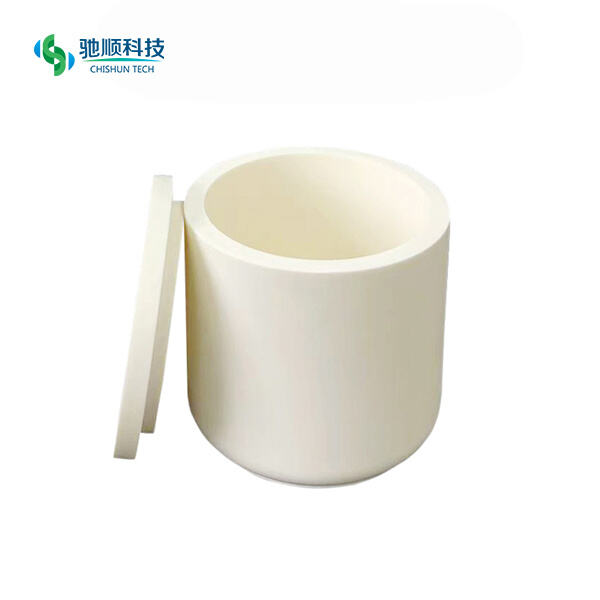

Ceramic ball mill is made of ceramic material and used for grinding the materials into small particles by rotating a cylinder with ceramic balls. These grinders may be employed in various types of industries that demand the reduction of fine powders. The ceramic balls grind the materials in all directions, to grind the material in an even and efficient manner, thus, the final end product is of other good quality.

The advantages of grinding with a ceramic ball mill can be summarized as follows. The main advantage of ceramic ball mill is that it can be used for continuous operation, and it is easy to adjust the granularity of the products. What it means is that such knives need less maintenance and more affordable in the long run. Ceramic Ball Mill also is from the grinding process, which is more even and high efficiency.

How Ball Mills Work (Engineering and Mining) glimpsedefense.com Product Introduction A high efficiency and energy saving ball mill with rolling bearing Capacity Up to 160t/h Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

Ceramic ball mills could be in high effective in materials processing in most cases. One possibility is to decrease the energy consumption needed to pulverize materials. Ceramic balls can grind the materials more effectively and gently than old-fashioned steel balls, and in our opinion, more work gets done in the process. At the same time, ceramic ball mills have the features of fine grinding and super fine grinding that ball mills don’t have so it can bring more efficient milling and better grinding effect to everyone!

Maintenance of a ceramic ball mill is the key to the efficient grinding of materials. There are some maintenance tips to use for ceramic ball mill in your factory, such as cleaning the machine after the production work, and even doing a full-check for the machine when it is empty. Such maintenance can help you to extend the life of your ceramic ball mill, and it has the efficiency of subsequent grinding.

Ceramic Ball Mill Compared with other grinding mills is that its final product and with same power, the capacity of Cera… Compared with other grinding mills is that its final product and with same power, the capacity of ceramic ball mill together with air classifier is larger and it can be achieve more fine feature. And one of the key differences is that the balls are made of ceramic instead of steel – which produces a more efficient grind, leading to a finer ground end product. Furthermore, the ceramic ball mill has the features of the small investment, small loss and high yield, easy mixing and grinding, even particle size of products, high grinding efficiency, which can save a lot of equipment and manpower investment for enterprises, and has more cost-effective investment in the long run.

We could be the ceramic ball mill manufacturing that combines research manufacturing, sales, and service. As one of the Hi-tech major Enterprises of Torch Arrange CHISHUN was house to the best technical personnel hold a number of patents, also cooperated with local professors of NJU, NUST and HHU.

Our items are used ceramic ball millin geology and mining and metallurgy. Electronics Ceramics, building materials, plus ceramics. Chemical industry plus light industry. Medicine, cosmetology. Protection for this environment.

Our team try dedicated to supplying you with of apparatus the ceramic ball mill. Each member of our team is faithfully accountable and dealing for virtually any little bit of work they do. We have been certain that our talents and efforts will bring you better work.

Our instruments are ceramic ball mill, yet feature-rich efficient, and low in noise, which can make them often instruments perfect accumulate particulate samples (four samples in 1 test) in scientific research institutes such as universities, colleges and universities as well as in corporate research laboratories.