Cool Cutting Machine - The Cryogenic Mill

In the world of industry and laboratory research, one such amazing tool is cryogenic mill. The magical device can crush different materials to powders, and it works at an amazing low temperature with liquid nitrogen. It is used in a wide array of research fields including oncology, geosciences and food science as it brings various advantages with applications which position this technology at the forefront for continual contribution to scientific research.

When it comes to the cold grinding method used by a cryogenic mill, one of its main advantages is that relevant properties of processed products are retained. Nanjing Chishun cryomill can preserve the integrity and vital qualities of the product. Something essential when dealing with food or pharmaceutical industry where all aspects such as purity, quality etc. are incredibly important for them. During processing stage itself by freezing any organic matter using liquid nitrogen while keeping it away from air exposure at very low temperature opportunity window that is given for completing other advanced stages within a regulated environment.

A novelty procedure compared to the classic grind also makes it unique, by presenting a system of low-temperature process developed exclusively for this mill. It makes possible this system is that additional means for conversion of the particles in solution during processing slowly and uniformly, thus preserving to a greater degree materials physics. Simultaneously, this novel technology helps to circumvent the problem of grinding hard-to-machine materials like rubbers and plastics or elastomers which makes it a versatile device that is irreplaceable in different industries.

Safety is paramount in any laboratory environment, so the cryogenic mill is protected by a full safety system to protect operators and samples during processing. For the safety of researchers and technicians alike, this Nanjing Chishun Products comes with features such as emergency stop buttons and numerous Safety Interlocks to provide a fool proof working environment.

Using the Cryogenic Mill

Likewise, the cryogenic mill comes with multiple possibilities to serve as a straightforward tool assisting research and technicians in their laboratory-phase of work. The primary use of this machine is in the ultrafine grinding and sample division (bland other applications) for the more delicate materials, such as hard plastics soft plastic or substances that are subject to phase changes. Moreover, the high quality characterized by precision and accuracy in cryogenic mill is dedicated to QC analysis.

Cryogenic Mill Operation

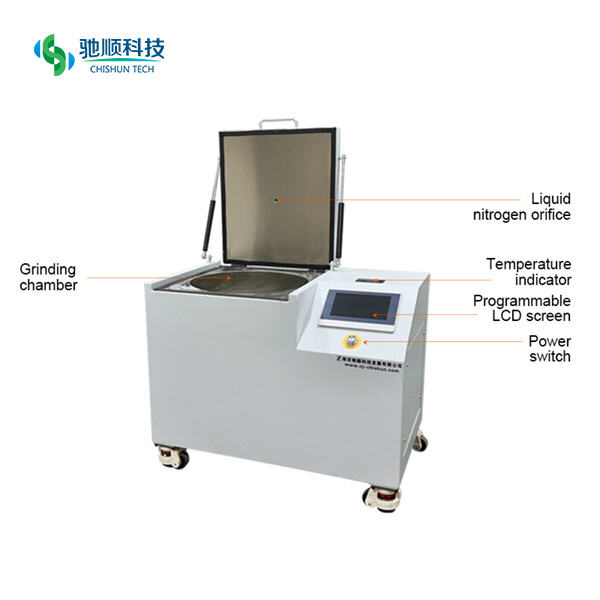

The requirements for setting the cryogenic mill are simple: place your sample into milling chamber and then set parameters (cooling time, milling duration and feed rate) in control system. After the parameters are set, the machine runs automatically and requires your attention until it's done.

Service and Maintenance

The cryogenic mill is also supported by a variety of after-sales offers including technical support and service to complete on-site routine maintenance checks. Experts are at hand to resolve any kind of problems that may ensue, maintaining the state of health and efficiency from time to time.

A good cryogenic mill can provide a uniform quality of the final product, in terms of both dimension and industrial standard. For high-quality coffee, all equipment is made of high-temperature materials that are heat and wear-resistant - reliability and durability.

Our items are used Cryogenic millin geology and mining and metallurgy. Electronics Ceramics, building materials, plus ceramics. Chemical industry plus light industry. Medicine, cosmetology. Protection for this environment.

Our instruments are Cryogenic mill, full-featured, full of effectiveness plus reduced in noise which make them perfect instruments obtaining particulate samples (four samples every test) in scientific analysis institutes, colleges and universities, plus in business research laboratories.

We certainly are a Cryogenic mill manufacturing that blends analysis, manufacturing, sales and service. Among the Hi-tech major Enterprises of Torch Plan, CHISHUN possessed a team of exemplary technical personnel. They even hold several patents. They even cooperated with local professors from NJU, NUST plus HHU.

All of us is invested in supplying both you and tools of this Cryogenic mill. Every member of all of us is dedicated plus accountable with their perform. We have been certain that our abilities and work makes it possible to achieve greater outcomes.