Planetary Ball Mill / Jenis Laboratorium / 04L

- Gambaran Umum

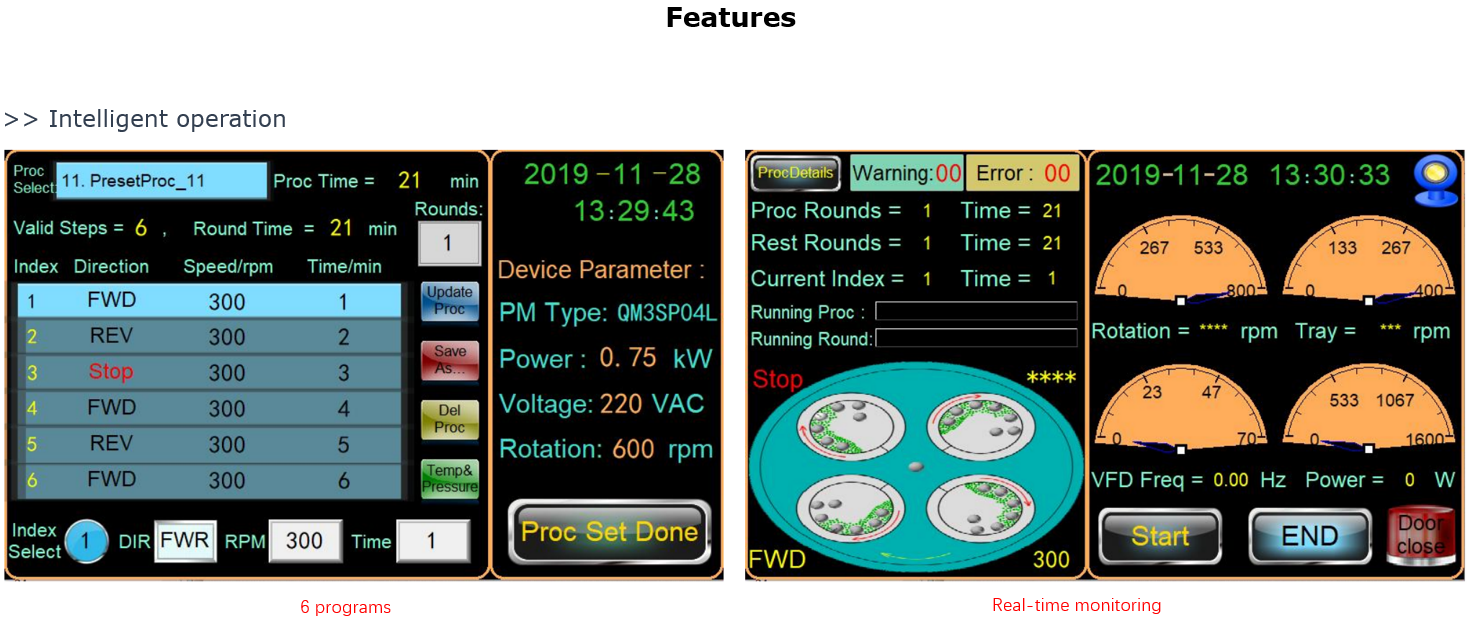

- Fitur

- Spesifikasi Teknis

- Video

- Pertanyaan

- Produk Terkait

|

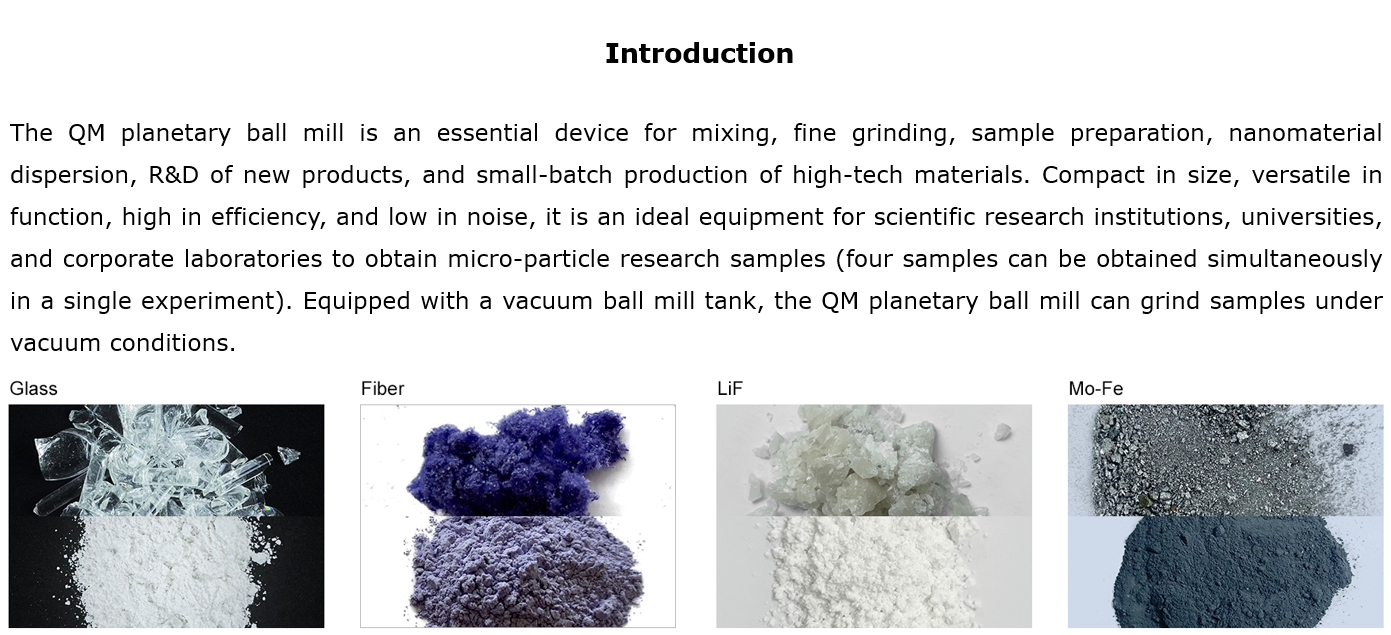

Aplikasi: |

Bahan elektronik, tanah, bahan penerbangan angkasa, baterai, keramik, mineral, metalurgi, dll. |

|

Contoh yang sesuai: |

Lembut, keras, rapuh, serat, kering atau basah |

|

Volume pemberian maks. : |

2/3 dari tabung penggiling |

|

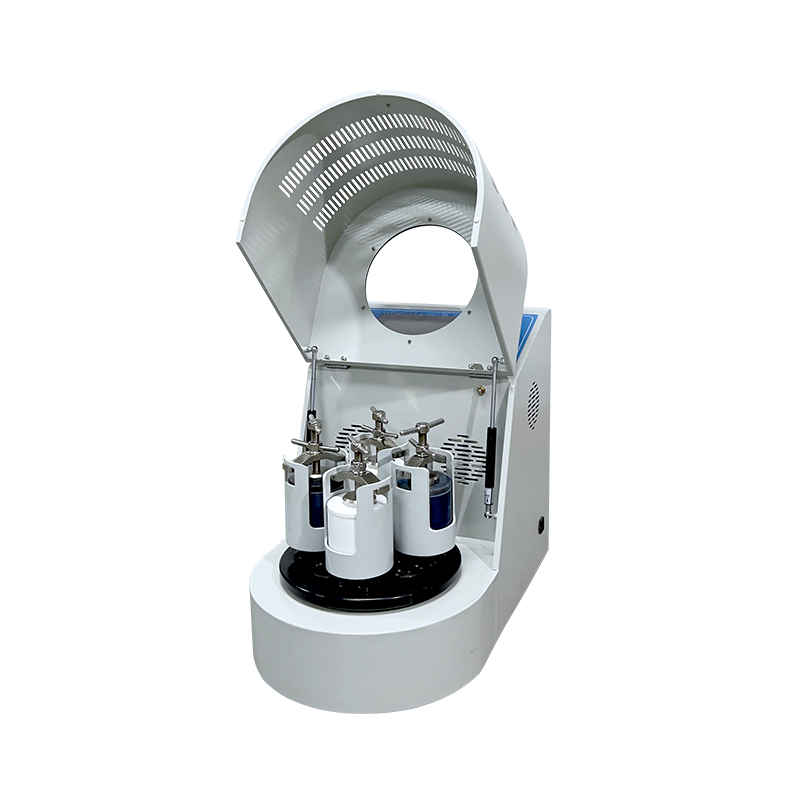

Penggilingan vakum: |

opsional |

|

Ukuran pemberian: |

tanah≤10mm lainnya≤3mm |

|

Ketelitian akhir: |

0,1μ m |

|

Waktu alternatif: |

1-9999menit |

|

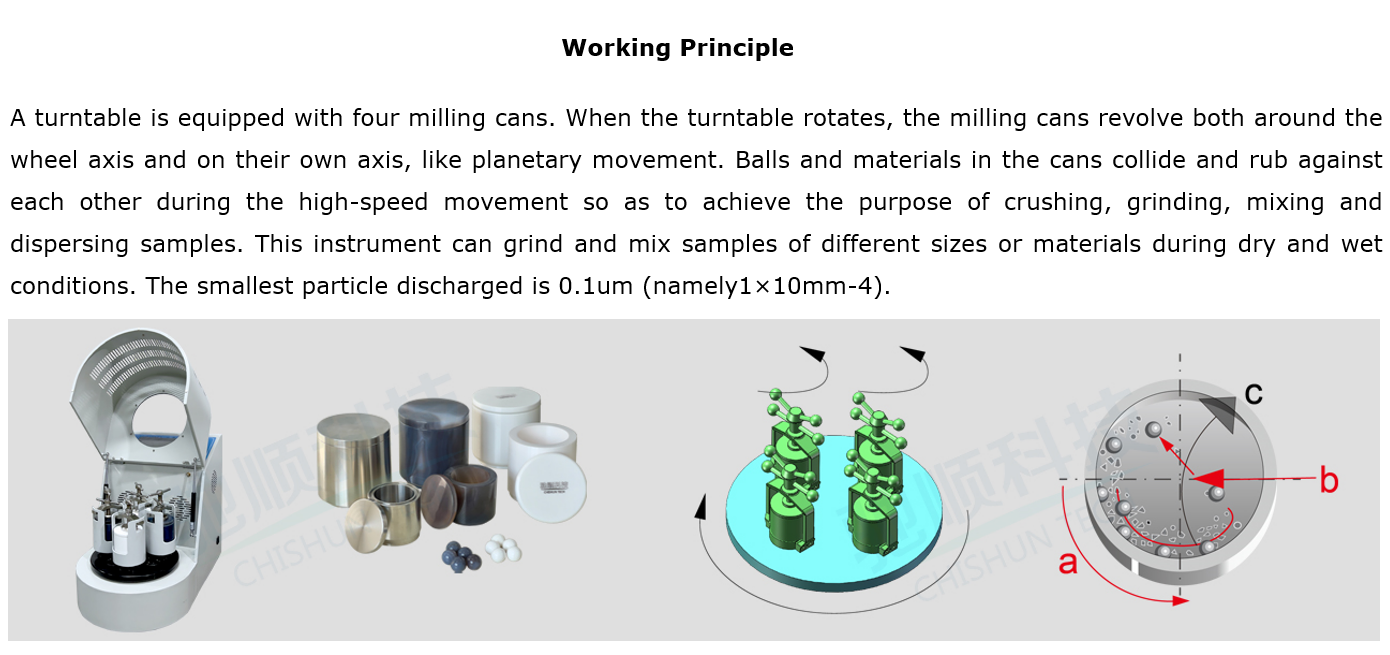

Rotasi |

800rpm |

|

Tabung penggilingan: |

50ml, 100ml |

|

Tabung vakum: |

50 ml |

|

Sertifikat: |

UL、CE |

|

Kekuatan: |

220V 0.75kw 50~60Hz |

|

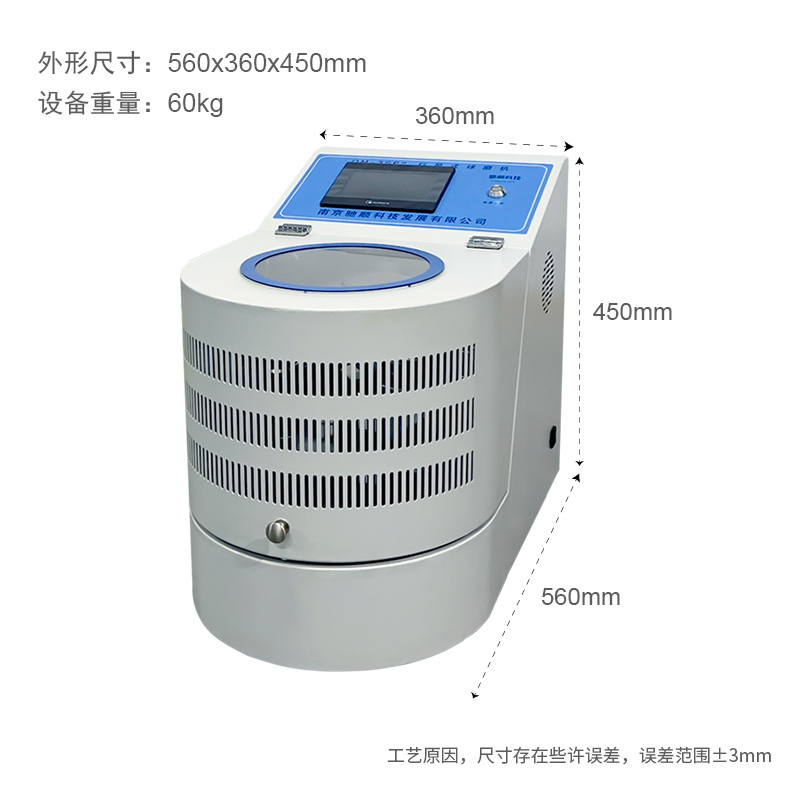

Dimensi: |

56*36*45cm 60kg |

|

Penyimpanan data: |

120 set proses |

|

Pemantauan data: |

Pemantauan real-time status operasi, mendukung peringatan kesalahan |

|

Operasi dapat diprogram: |

6 langkah operasi yang mendukung sunting/hapus |

|

Mode kontrol: |

layar sentuh HMI 7", Berbagai mode operasi (operasi bolak-balik maju dan mundur, operasi interval, operasi berbasis waktu) |

|

Bahan tabung: |

Baja tahan karat, vakum, batu akik, zirkonia, alumina, PTFE, nilon, karbida tungsten karbida, dll . |

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH