In the class of size reduction machinery the conical ball mill is built to do one job only; grinding. The special device is used for grinding the material one time, and powders are repeatedly produced using this machine, and the machine is widely used in mining, the construction and chemical industries.

Conical Ball Mill Working Principle It is a generally recognized fact that for economic reduction of any material, it is desirable to perform such reduction in steps or stages, removing that material which is sufficiently fine as soon as it is reduced and grinding it still finer in some device more adaptable to this finer reduction. It is partially filled with grinding bodies: cast-iron or steel balls, or even flint (silica) or porcelain bearings. As the drum rotates, the media should ideally form a monument of material on top thus crushing the product into smaller particles before finally grinding said particles to a fine powder. Uniform Products with the Kason Conical Mill In the past, developers of a new plant typically applied a factor, typically 3.5 W/ F, to the Bond c factor and the result made up the motor power to reach the installed power level.

Beneficiation of a concentration of underground copper-nickel sulphide ores [16] using a conical ball mill [17] There are several benefits comparing to other process.

A number of use of Conical Ball Mill: This is to be used for industrial grinding. One of the primary benefits is it's energy-efficiency due to its low operating level, thanks to the low quantity of waste on the surface needing to be put in motion. Moreover, the mill shape is conical, providing more surface area for more efficient grinding. Additionally, the Conical Ball Mill has an application in many industries, not only in ore grinding but also in regrinding of pigments and the likes as well as in the soft substance processing.

When selecting the proper grinding equipment, it is necessary to examine the amount of dust produced as compared to any required dust control features. Although there are other grinding machines used in the same industry, Conical Ball Mills are built quite different from them. Conical Ball Mills as compared to the other types of grinding mills include the following: (a) grinding more. economically than other types of mills. Their conical form also offers improved control over particle dimension distribution and in the appearance of end products.

Maintenance and Use of your Conical Ball Mill If you regularly check the machine and its parts, you can catch issues before they cause much damage. And, lubricate and replace worn parts as necessary. It also helps you avoid clogs and assures smooth operation by preventing buildup in the mill. With these guidelines as your reference, you can prepare your Conical Ball Mill for the long reliable maintenance service it is capable of delivering to your production line.

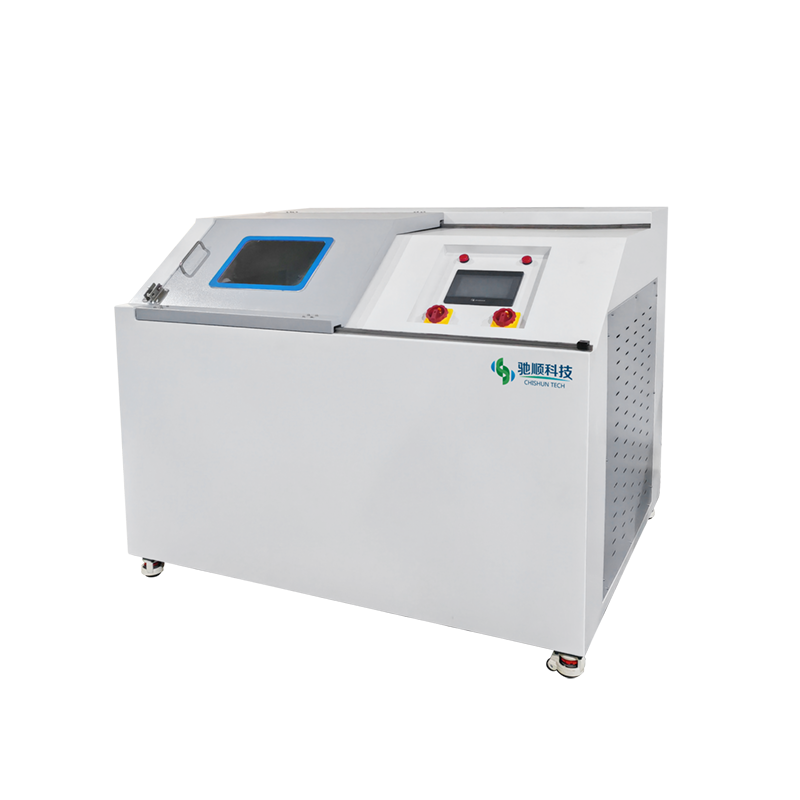

We could be the conical ball mill manufacturing that combines research manufacturing, sales, and service. As one of the Hi-tech major Enterprises of Torch Arrange CHISHUN was house to the best technical personnel hold a number of patents, also cooperated with local professors of NJU, NUST and HHU.

Our items are conical ball millfound in geology and mining and metallurgy. Electronics Building materials, ceramics. Chemical industry Light industry, chemical industry. Medicine, cosmetology. Environmental safeguards.

All of us is invested in supplying both you and tools of this conical ball mill. Every member of all of us is dedicated plus accountable with their perform. We have been certain that our abilities and work makes it possible to achieve greater outcomes.

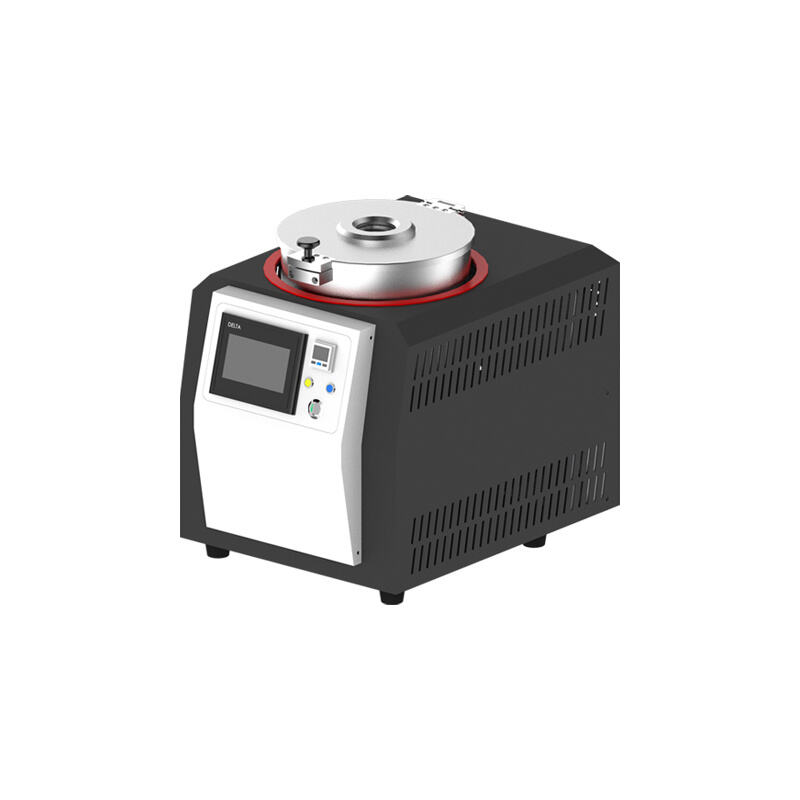

Our items are conical ball mill and features, highly efficient, and quiet. They've been ideal for capturing particulate samples 4 samples per experiment) at research institutes for scientific research and corporate labs.