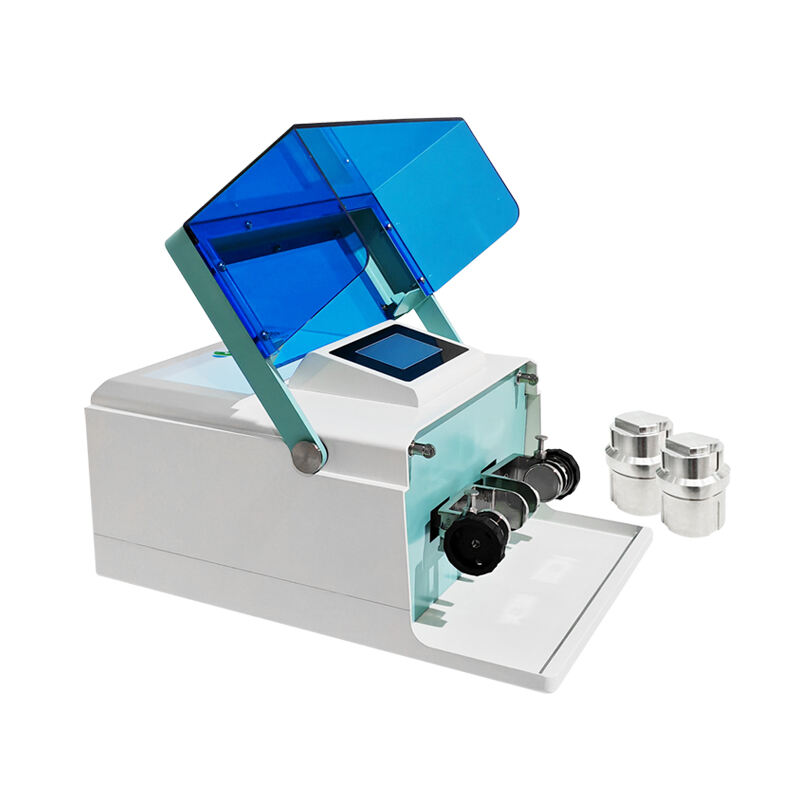

Machine Tool: Small Vacuum Furnace To Process Materials

Introduction:

The right tool can make all the difference, especially when working with small wares. A low-vacuum furnace is a popular choice given its versatility, safety features and finely tuned accuracy.

Advantages:

There are more than a few benefits to using the small vacuum furnace and they all mean quite much as well. One is its small size, which make it easy to use in tight spaces. In addition, a vacuum ensures that substancesensitive materials are protected from contamination oxidation reactions and/or other adverse outcomes. Furthermore, these furnaces also have quick heat-up and cool-down times ensuring high energy efficiency with minimal maintenance ideal for processing small material samples accurately every time.

Small vacuum furnaces have experienced tremendous technological advancements throughout the years. These manufacturers also pieced together components that allowed real-time adjustment of the engine operation limits providing feedback to engineers or operators regarding thresholds like temperature, pressure and gas flow but were often slow in response. In addition, these systems allow precise calibration of temperature profiles for easier customization of heating and cooling rates. Moreover, the advanced heating elements like molybdenum and tungsten have improved uniformity as well as consistency in a vast range of heating processes.

Whether it is cutting saw or dye cut, safety of any tool used in processing material should be the first priority. Small vacuum furnaces are available with a plethora of safety features - perfect for working with hazardous or reactive materials when correctly controlled. An example of this would be that they have built-in emergency shutdowns which initiate if the pressure or temperature goes really abnormal. The complex layers of protection against vacuum leakage, overheating and power surge for the furnaces allows users to work in a more secured way lessening! Risks that can also lead into accidents!

All provide near-universal application, forming the heart of small vacuum furnaces used in every conceivable materials processing task. Utilizes for this type of furnace include sintering metals, ceramics and composites; heat treating small components such as gears, bearings and microelectronic parts - all of which are crucial in the aerospace automotive or medical device industries. They are also used for the brazing, annealing and stress relieving of small samples - they are an integral tool in research as well as quality control.

How to Use:

How Does A Small Vacuum Furnace WorkStep 1: Make Sure Everything Is Working As It ShouldBefore beginning the process of operating a small vacuum furnace, ensure that it is securely plugged to a power source, and all safety features are functioning. After this, the materials to be processed are properly loaded into the furnace chamber in such a way which ensures they are both clean and dry. The resulting temperature profile was now adjusted by means of a digital control system, the heating process commenced. Customers track the time and temperature until they achieve this processing cycle. In the end, gases are shut down and chamber is opened after which processed material available for Retrieve from furnace.

Regular vacuum furnace maintenance and servicing is key to keep a small unit operating at full speed. Routine inspection, calibration and repair can be performed by technicians trained for the job to make sure that it is running on its peak efficiency. Customization and ODM/OEM is also possible as special customer version, for example to maximize the lifetimeership with best performance.

we are specialized in providing you with machines for the Small vacuum furnace. Each member of all of us works diligently and is accountable for the ongoing perform they do. We wish which our commitment and knowledge will allow you to create best work.

Our instruments are Small vacuum furnace, yet feature-rich efficient, and low in noise, which can make them often instruments perfect accumulate particulate samples (four samples in 1 test) in scientific research institutes such as universities, colleges and universities as well as in corporate research laboratories.

We are a Small vacuum furnacemanufacturing that integrates studies production, sales, plus service. CHISHUN is one of the Hi-Tech significant Enterprises of Torch Plan, had a reputable bunch of, held an amount of patents, along with worked with local faculty members at NJU, NUST, and HHU.

Our products are used Small vacuum furnacein mining, geology, electronics, metallurgy materials ceramics, chemical industry, medicine, light industry cosmetology protection environmental etc.