Tumble mill works on the principle of impact and attrition. The mill comprises a hollow or cylindrical shell having grinding media (steel balls or rods) to perform the grinding of ores, coal/coke and other materials. The grinding media feed material enters the drum before being thrown off towards the drum shell by centrifugal force. When the drum rotates, the grinding media, along with the mineral material within the drum, cascades and puts the material through the grinding action by the crushing of the particles between the grinding media.

There is a broad range of applications for tumbling mills across many industries. They crush materials including, various types of ores, minerals and chemicals. Tumbling mills are also widely used in the cement, ceramic and paint industries. In the food industry, tumbling mills are designed for grinding of foods (e.g. chocolate and spices).

A Review on Tumble Mill: The 3 Common Types of Tumble Mill are known as Milling Machine in Manufacturing of Powder Materials publication by Adyan Miftakhidin Jurnal Teknologi Mineral FT UNRAM 20162 43 1 4 afl QuarriesSolutions in Production Plant Tumble mill is used in mineral processing cement and power plants tradisional Mampu menghasilkan partikel dengan ukuran MESIN TUMBLETUMBLE MILLMacam macam ukuran partikel yang diinginkan l/d ratio bulk densitas porositasSize of particle Ratio betweenLength anddiameter bulk densityPorosity of Internal Tumble Tumbler merataPengoperasianMesinPemutar Umur mesin pemutarAlat penumbuk.

The tumble mills in the above-mentioned manufacturing are classified into several types, and then applied to various working applications. The ball mill, rod mill and pebble mill are common types of tumble mills. Ball mills are the most commonly used type of tumble mill used for grinding material in the mining process and various other industries. Another project for rod mills is grinding of metal ores whose materials for processing are extremely hard with too much regularity. They also grind materials that are hard and abrasive, such as silicon carbide and other similar hard materials. Pebble mills are generally smaller than ball mills and use small size of the impact of mineral.

Tumble mills offer many benefits in material processing. The most obvious would be that tumble mills are able to produce around a certain particle size. In industries such as mining however, it is important to reduce size to a size sufficiently small that the materials can be processed further. With the ability to process the biggest lot sizes of any type of grinding equipment, tumble mills are fast and are capable of processing continuous runs and operations.

It is also beneficial to employ tumble mills in that they are capable of handling a broad variety of materials. Whatever he looks upon—whether it revolves in the skies above, or grows in the earth beneath, or in the water beneath the earth, or in the fire that issues from the water, or in the quarry where he digs—or, grinding the ore or the mineral or the chemical, in the channel and the trough of the tumble-mill—he is all of the one mind in working out his formulae, and models the forms of his creation in his own image? They are also very convenient to operate and maintain which make them a dependable machine for factories.

In order to keep your tumbling mill operating without issues you will need to follow just a few simple maintenance-related procedures. One of the most crucial items to maintain on a ball mill is the lining system and the blades of the drum. The grinding media can wear down over time, and do not last indefinitely. You can maintain your tumbling mill in peak operating condition by keeping a regular clean on the media.

we are specialized in providing you with machines for the tumble mill. Each member of all of us works diligently and is accountable for the ongoing perform they do. We wish which our commitment and knowledge will allow you to create best work.

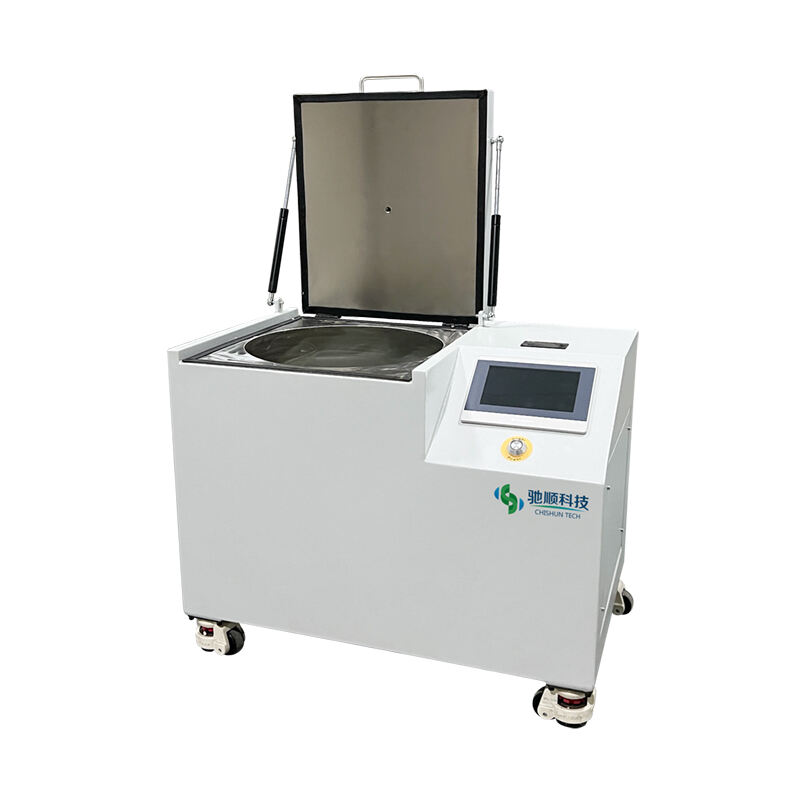

Our instruments are tumble mill, yet feature-rich efficient, and low in noise, which can make them often instruments perfect accumulate particulate samples (four samples in 1 test) in scientific research institutes such as universities, colleges and universities as well as in corporate research laboratories.

We are a tumble millmanufacturing that integrates research, production, sales and services. Being 1 of the key Hi-tech Enterprises of Country Torch Plan CHISHUN was in fact home to an excellent group of personnel and hold many patents. in addition to dealing with local teachers of NJU, NUST and HHU.

Our products is used tumble millin mining, geology metallurgy, electronics, building items chemicals, ceramics light industry, medicine, environmental protection, cosmetology, etc.