- Overview

- Features

- Inquiry

- Related Products

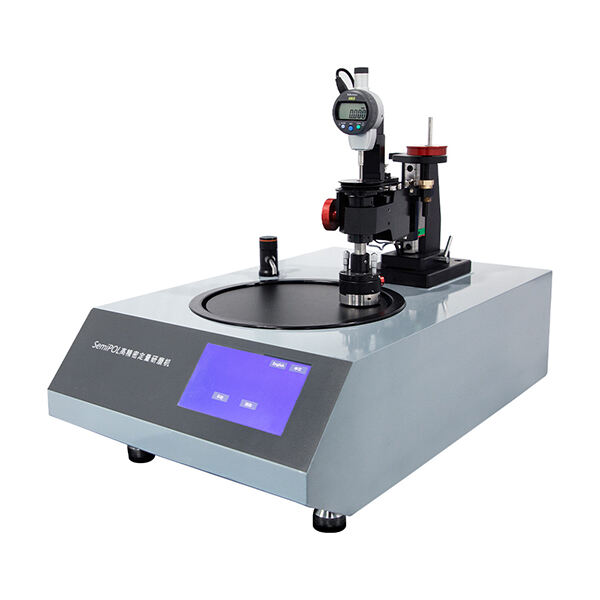

SemiPOL are capable of performing precise grinding and polishing of various materials (integrated circuits, semiconductor wafers, optical components and optical fibers, petrographic structures, precision metal parts, etc.) for microscopic(SEM, FIB, TEM, etc.) analysis. The target accuracy can reach micron level. It is mainly used for parallel grinding and polishing, quantitative thinning, continuous slicing and other precision applications. With more accessories and fixtures, it can make the grinding and polishing of complex and special-shaped parts easier and more convenient.

SemiPOL can monitor the amount of material removed in real time, or set the amount of material ground and achieve unattended operation. The servo drive motor can control the rotation speed and swing amplitude of the positioning head to Improve flatness and finish of grinding and polishing.

|

Model |

SemiPOL |

|

|

Working disc |

Diameter |

8-10 inch(203/254mm) |

|

Speed |

0-350rpm,continuously viable speed |

|

|

Direction |

CW/CCW |

|

|

Power |

750W |

|

|

factory inspection |

Flatness < 2um |

|

|

Sample movement head |

Speed |

0-50rpm,continuously viable speed |

|

Direction |

CW/CCW |

|

|

Rotation |

Yes,with adjustable amplitude |

|

|

Oscillation |

Yes,amplitude and speed are adjustable |

|

|

factory inspection |

Perpendicularity to the disk <2um; parallelism <2um |

|

|

Maximum removal capacity |

10mm |

|

|

Electricity |

Power supply |

220VAC |

|

Panel |

7-inch touch screen |

|

|

Dimension |

WxDxH |

700x430x580mm |

|

Weight |

57kg |

|

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH