Key Words: high frequency induction furnace,special machine,human life It is responsible for heating and melting the metals quickly while giving a cost-cutting solution to businesses. This blog post will explore the benefits, advances in; modern safety devices, operations considerations and services that are provided as well as quality assurance practices along with a variety of applications for this crucial piece of equipment.

Known for a high throughput, the ITC industrial slab heater can melt light to moderate metal loads at an efficient power level and is powerful in function. This is accomplished via induction melting, where heat directly transferred into the material being melted without spending unnecessary energy loss. Apart from that, this furnace is cost-effective and an energy-efficient option for any industry looking forward to saving the fuel consumption. The Philips also benefits significantly from the quality of goods produced by it, exhibiting consistency on such front which is what many industries look for when seeking reliability and performance.

High frequency induction furnace technology has come a long ways over the years. The establishment of intelligent control systems has made its operation easier, allowing users to have more melting process control. It also features improved insulation in the furnace design that reduces heat loss and increases its energy efficiency. One of the ways in which new models are better if these instances does not occur is by adding a water cooling system to keep the forge temperature during melt, solidifying The continuous evolution as technology advances

Operation of the high frequency induction furnace is carried out on maximum security, same has multiple safety devices to ensure a safe working place. Where operators will be on site an emergency stop button is located near the automation. There is also a protection system that will shut down the furnace if there will be any malfunction so no harm can happen and it makes sure all accidents are prevented.

How to use The High Frequency Induction Furnace Step by step Instructions

High Frequency Induction Furnace - The Basic Working The very first thing you want to do (aside from making sure the furnace is even connected and power supply provided) Once you have this connected, fill the material to melt into it (in our case 3D-printer press), and turn on by damped. Continuous monitoring of melting process is the key for everything to go as expected After melting is finished, turn off the furnace and wait for a while until it becomes cold enough so that you can take out pieces of material - such unlock proceedures make work safe and efficient.

Lower price offers to the customers would be there in this kind of service Comprehensive Services for The High Frequency Induction Furnace

It helps the customers a lot as some of them are consumers will be freed from numbers processes and for high frequency induction furnace Manufacturers there is given a full range of support services. Those services include installation, repair and maintenance of the furnace to provide peak operating results. Others offer training sessions on how operators can safely and effectively use the furnaces. These services are very useful for keeping the operational efficiency of their furnace at its best level, reducing downtime and must be done to reduce the potential risk of accidents.

Performance and Longevity: The high frequency induction furnace is a product that probably has the most effect on quality of it. Durable, high quality furnaces that will reliably produce great products. The manufacturers use high-quality materials and manufacturing processes to ensure that the furnace is durable, reliable. Furthermore, the merged high-grade heaters come with state of the art control systems contributing to efficient operations and ensuring safety due recognition towards quality standards associated in this vital system.

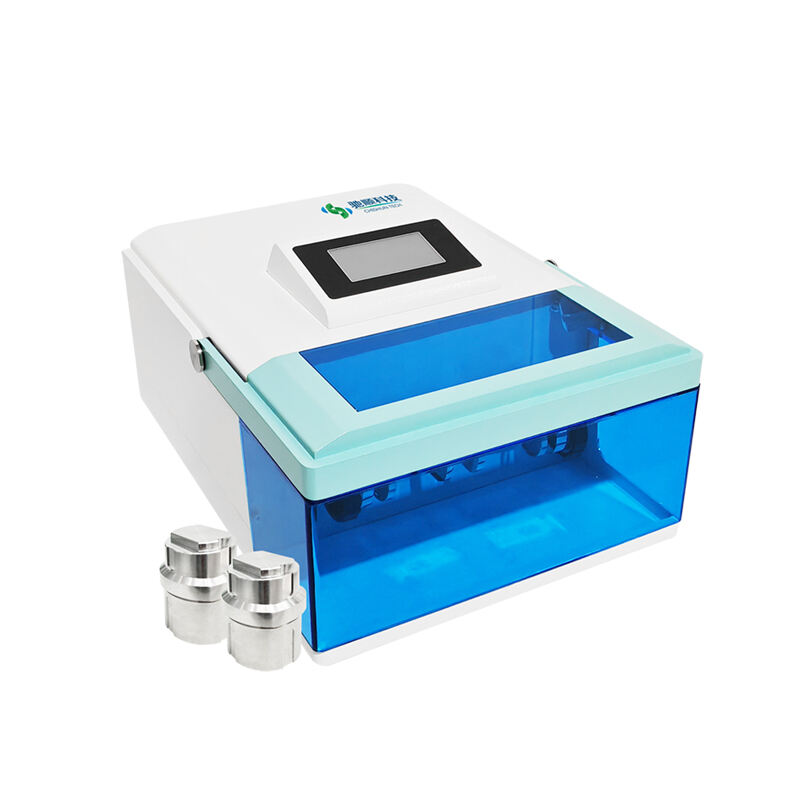

Our instruments are High frequency induction furnace, feature-rich efficient, and reduced in noise, perfect instruments of the number of particulate sample (four examples per test) in research institutes for systematic research also universities and colleges also corporate research labs.

We have been a High frequency induction furnacemanufacturing that centers on research, production, and serving. The quantity of patents, along with working with local teachers of NJU, NUST plus HHU as one of the most important Hi-tech Enterprises of Country Torch Plan, CHISHUN possessed the most skilled technical personnel hold.

All of us is aimed at supplying you and hardware of this High frequency induction furnace. Every person inside our team works diligently and it is responsible for the ongoing work they do. We hope which our knowledge and effort will assist you to create better perform.

Our items are High frequency induction furnacefound in geology and mining and metallurgy. Electronics Building materials, ceramics. Chemical industry Light industry, chemical industry. Medicine, cosmetology. Environmental safeguards.