VRBM1600 Variable Speed Ratio High-Energy Ball Mill (Independently Adjustable Revolution & Rotation)

- Overview

- Parameter

- Features

- Inquiry

- Related Products

Introduction:

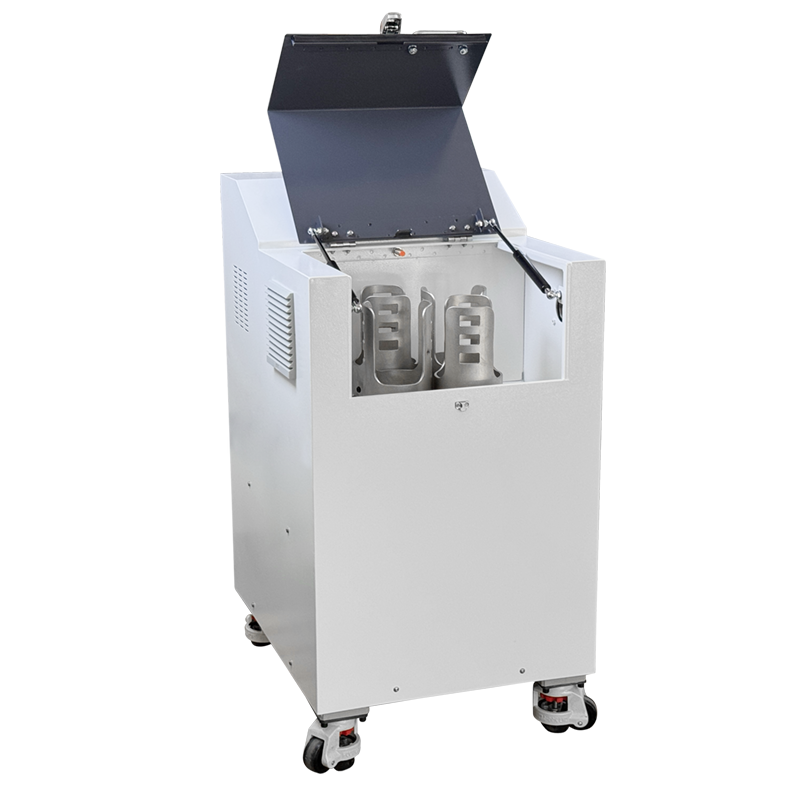

The VRBM1600 Variable Speed Ratio High-Energy Ball Mill is a planetary-type high-energy mill capable of reaching rotation speeds up to 1600 rpm. It is designed for grinding, mixing various powder materials, or performing mechanical alloying of metallic materials (compatible with 4×500ml milling jars).

The mill features independent control of both jar rotation (up to 1600 rpm) and planetary revolution (up to 400 rpm). This unique capability allows operators to freely adjust the revolution-to-rotation speed ratio according to different material requirements, enabling precise modulation of impact forces and shear forces during ball milling or mixing processes. Such flexibility ensures optimal processing results for various grinding and mixing applications.

The equipment is widely applicable for synthesizing novel nanocrystalline materials, functional materials, and composites through methods including:

• Mechanical alloying

• Mechanical compounding

• Mechanochemistry

Working principle:

The VRBM1600 Variable Speed Ratio Planetary High-Energy Ball Mill operates on the planetary motion principle. Grinding balls move at high speeds inside the milling jars, utilizing intense friction and impact forces to pulverize samples – capable of grinding materials down to below 1μm rapidly.

Its defining feature is the arbitrarily variable transmission ratio between jar revolution and rotation speeds. By adjusting this revolution-to-rotation ratio, users can freely modify grinding conditions without limitations. This flexibility allows the mill to simulate grinding processes of various conventional ball mills.

Paramter:

|

Model |

VRBM1600 |

|

Brand |

CHISHUN TECH |

|

Features |

Independent Speed Control: Sun wheel revolution speed (jar carrier) and jar rotation speed can be independently controlled. Adjustable Speed Ratio: Users can freely set the revolution-to-rotation speed ratio to regulate impact and shear forces during ball milling, achieving optimal grinding/mixing results. Maximum Grinding Capacity: 4 × 500ml jars Programmable LCD Touchscreen: Set milling programs, revolution/rotation speeds, milling time Supports process data storage Applications: Material alloying, ball milling, mixing, homogenization, etc. Optional Semiconductor (Peltier) Cooling System (-10℃): Programmable independent control of cooling temperature and duration Integrated defrost function |

|

Workbench |

Configuration: 4pcs (support simultaneous processing with either four jars or two jars symmetrically positioned) Safety Mechanism: Dual safety locks with rotary locking mechanism Grinding Chamber: Fully enclosed yet easily accessible design Compatible Jar Sizes: 4 × 100ml jars | 4 × 250ml jars | 4 × 500ml jars (Note: Adapters required for jars <500ml) |

|

Speed |

Independent Control: Sun wheel revolution speed (jar carrier) and jar rotation speed are independently controlled, enabling variable transmission ratios and centrifugal acceleration. Revolution Speed (Sun Wheel): 0–400 rpm, continuously adjustable Rotation Speed (Jar): 0–1600 rpm, continuously adjustable Centrifugal Acceleration: 136g Recommended Speed Ratio: Revolution : Rotation = 1 : -3 |

|

Feed & Final Particle Size |

Feed Size: Brittle materials: < 10 mm, Other materials: < 3 mm Final Particle Size: Wet milling: Average particle size < 1 μm Dry milling: Average particle size < 20 μm Key Influencing Factors: Final particle size is dependent on material properties and process parameters including: Feed size, Grinding media selection, Milling duration Minimum achievable particle size: 0.1 μm (per customer feedback and testing data) |

|

Grinding Jar Specifications |

Jar Capacity Configurations: 4 × 100ml | 4 × 250ml | 4 × 500ml Jar Material Options: Stainless Steel; Hardened Steel; Zirconium Oxide; Agate; Alumina; Tungsten Carbide; Vacuum-Sealed; PTFE (Teflon); Nylon; Polyurethane Grinding Media Material Options: Stainless Steel; Zirconium Oxide; Tungsten Carbide; Agate |

|

Power |

AC220V,50~60Hz, 4KW |

|

Weight |

245kg |

Product Features

◎ Independent Speed Control: Revolution and rotation speeds adjustable separately

◎ No fixed transmission ratio: Freely configurable grinding conditions (key feature)

◎ 1600rpm high-speed nano-grinding: Precision particle refinement

◎ Programmable operations: Storage and preset program capabilities

◎ 4×500ml simultaneous processing: Multi-jar high-throughput grinding

◎ Advanced material synthesis: Compatible with mechanical alloying, mechanochemistry & nanomaterials R&D

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH