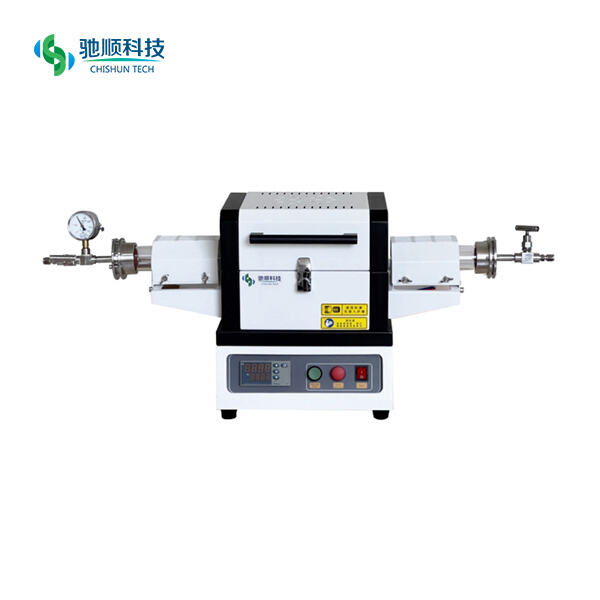

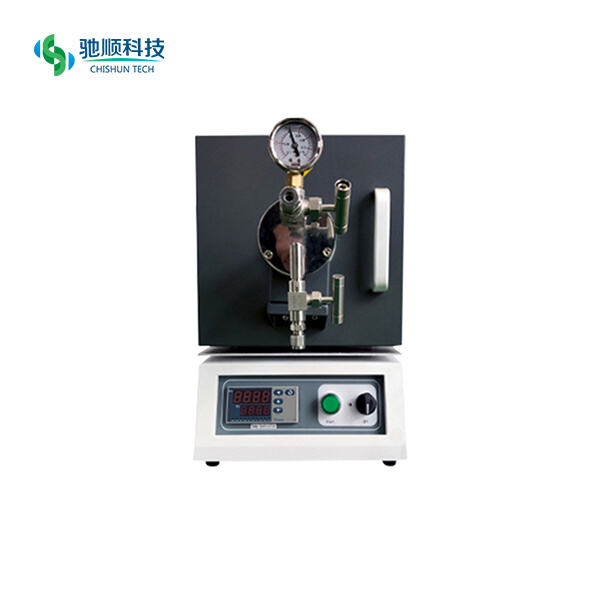

Iisithuthi sokuvibisa zineziko ezilula ukusebenzisa, zisetshenziselwa ukunciphisa ubungakanani beezinto, ngokugcina le zinto. Ziyi iisithuthi sokugcina nge-energi enkulu , ezisetshenzisa imali enkulu kwinqubo yokwenza izinto zingaphantsi. Iyakwazi ukwenza ngokukhawuleza nokusebenza kakhulu kwaye ingasetshenziselwa embangeni wonke. Masizadide njani iisithuthi sokuvibisa zisebenza kwaye ubunzima bezo teknoloji.

Iimixhaphulo ephinde-phindayo iVibration Grinder Machines ixabisela inkqubo yophando oluphinde-phindayo ekwenzeni inkcazo yobunzima. Isebenza ngokuthatha kakhulu ishiya eneziphumo ezifunekayo ukuzithabatha. Izinto zithabathwa ngokuhlinzeka kwamathuba aphinde-phindayo kungaphandle kwe. Le ndlela ibonakala njengendlela efanelekileyo kwaye inokuthabatha izinto ngokukhawuleza kunokwenzeka ngendlela eyodwa.

Inxalenye enkulu yokusetyenzisa ivibration mill kukuba umdalo uyasebenza kakuhle kwaye unceda umsebenzi. Ngelixa izinto zihlambalalwa ngokutshishala okuphakeme, lo mdalo uyahamba ngokukhawuleza, okukhawulezayera kunemini yokuqhuba. Kulo xesha ke ivibration mills zisetyenziswa ngempahla yezikhumbuzo, apho kudingeka ukugcina ngokukhawuleza kumlinganiso ophezulu wezinto.

Ukunciphisa ubungakanani kwi-vibration mill akukho mfuno. Xa iingcindezi zifakelwa kwindawo yobumba kwaye umgcini uqalisa, iivibrations zihlasela iingcindezi ngokuthi zizihlaba. Eli qhamo livakalisa ukuba iingcindezi zihlakulwe kwiingcindezi ezincinane ngendlela yokuchitha. Inzuzo yevibration ingaguqulwa ngokuchasisa ukuhlaseka kweenzuzo.

Iivibration mills zisetyenziselwa kakhulu kwiindustri ezifana nesiduko, iingcinga, kunye neemigodi. Iivibration mills zisetyenziswa ukuchitha iingcindezi eziphileneyo kwindustri yesifo. Ezi zixhobo zihlakula iimboni kunye neezinto ezinye ukuze zithintele izinto ezibonakalayo kuzo. Akunaphi na ifomu yobuso, iivibration mills zinesixa esikhulu ekuphindiseni ubungakanani.

Ukukhetha kwisithuthi sokuvibisa ngexabiso le ntshukumo Xa kukhethwa isithuthi sokuvibisa kwi ntshukumo eyihe, kufuneka ukhangele iintsomi ezininzi. Okokuqala, ubungakanani begrain ne ndawo yomgcazelo othathwayo kuyakuchaza ubungakanani nobunzima be 3) isithuthi sokuvibisa esifuneko. Ubungakanani besampuli esifuneko nobungakanani obuphakade bokwenza kuyakubangela inketho yesithuthi sokuvibisa. Kwaye kukho nento yokulungisa, engasohlalali ukwenza kwezimali, zonke ezingafunekiyo ngaphambi kokuthenga umgcini.

Izinto zethu zisebenzisa i-vibration mill kwiindawo zokukhupha, i-geology, i-metallurgy, i-electronics, iintlobo zomthwalo, iichemicals, i-ceramics, indawo yomthwalo omncinci, ubungcwele, ukulawula umoya, ukulawula amasiko, njl.

Izinto zethu ziyi-vibration mill, zinezinto eziningi, zinamandla, kwaye zingapheli. Zinokuba ziyinkulu ukususa amaparticulate (4 amacandelo ngalunye lwemfanekiso) emathabathini okufunda nokuziphatha kwiindawo zokufunda nezilabo zezibhalo.

Siyaphila kwi-vibration mill manufacturing eyayisikhundla sokufunda, ukuprodukha, kunye nokusebenza. Inani le-patents, kwaye ngenxa yokusebenza ngezifundo zaseNju, seNUST kunye neHHU njengenye yezibhalo zokugqibela kwiTorch Plan yaseMzantsi, uCHISHUN unabantu abanamandla kakhulu abasebenza kwiintlobo zokufunda.

Itimu lethu liyafuna ukubeka phambi kwenu izixhobo zokuvibrations. Umntu ngamnye wethu uyakholwa kakhulu kumsebenzi wakhe, kwaye uyakholwa kakhulu kumsebenzi onke othile oyenzayo. Siyakholwa ukuba imithombo yethu kunye nezindlela zethu zizokubringa umsebenzi omuhle.