Planetary Ball Mill / Lab Type / 4L

- Overview

- Features

- Techniacl Specification

- Video

- Inquiry

- Related Products

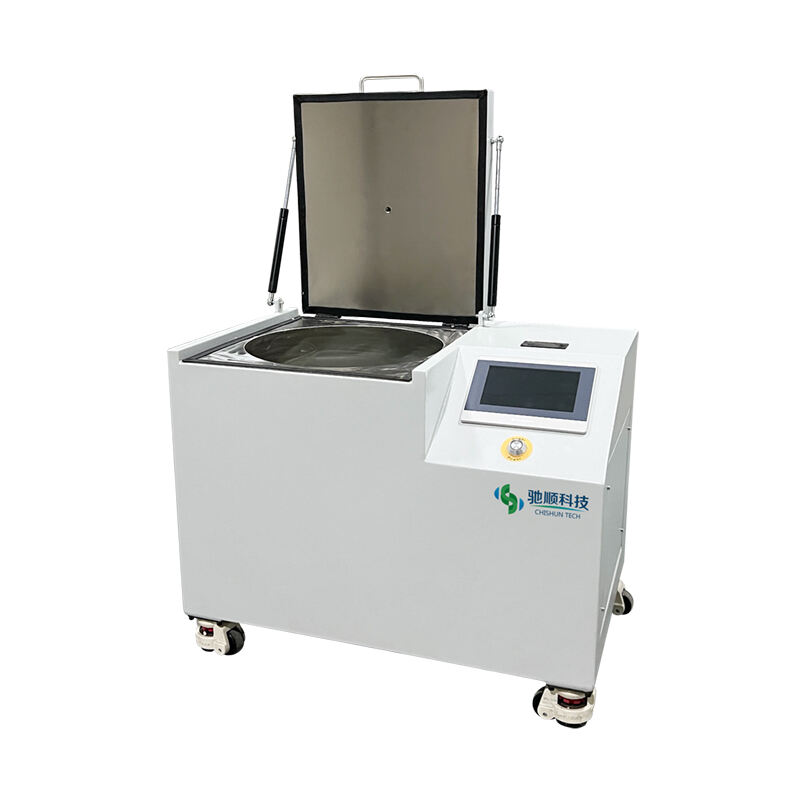

The QM planetary ball mill is an essential device for mixing, fine grinding, sample preparation, nanomaterial dispersion, R&D of new products, and small-batch production of high-tech materials. Compact in size, versatile in function, high in efficiency, and low in noise, it is an ideal equipment for scientific research institutions, universities, and corporate laboratories to obtain micro-particle research samples (four samples can be obtained simultaneously in a single experiment). Equipped with a vacuum ball mill tank, the QM planetary ball mill can grind samples under vacuum conditions.

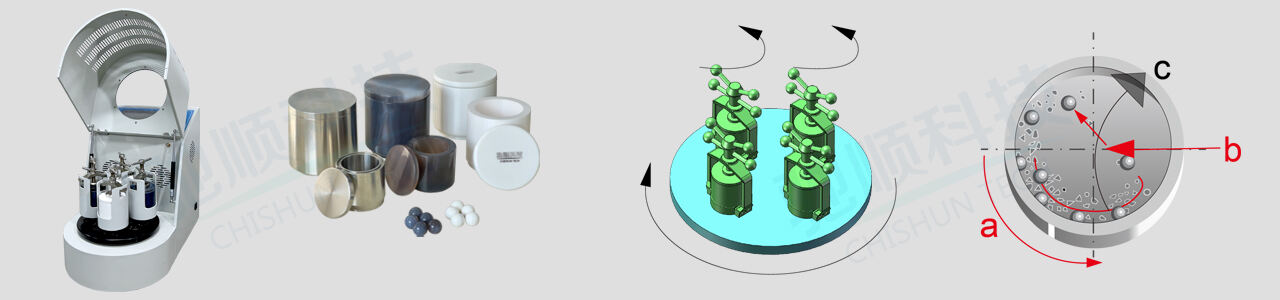

Working Principle:

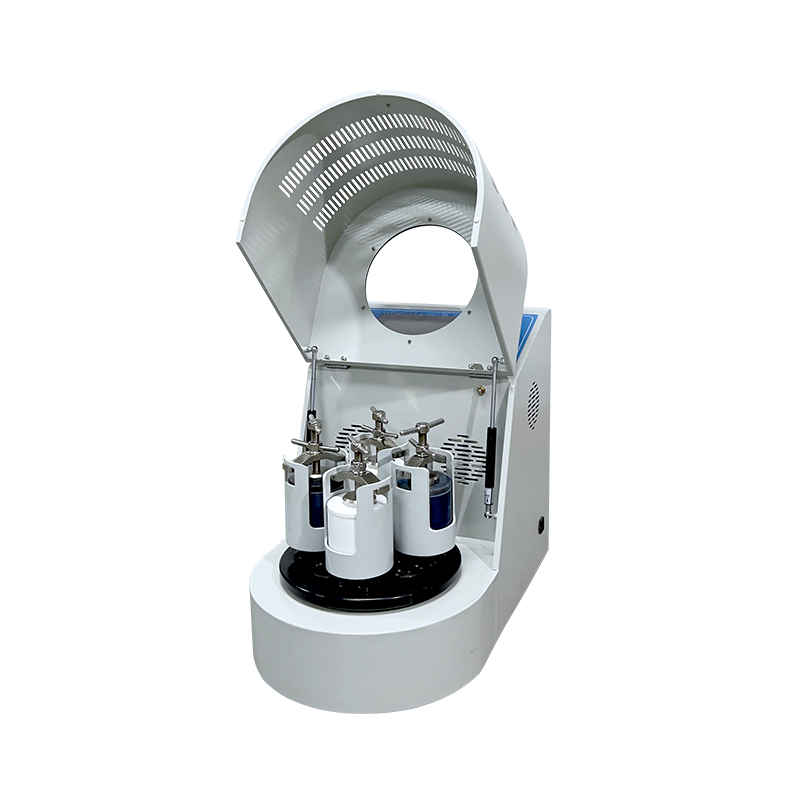

A turntable is equipped with four milling cans. When the turntable rotates, the milling cans revolve both around the wheel axis and on their own axis, like planetary movement. Balls and materials in the cans collide and rub against each other during the high-speed movement so as to achieve the purpose of crushing, grinding, mixing and dispersing samples. This instrument can grind and mix samples of different sizes or materials during dry and wet conditions. The smallest particle discharged is 0.1um (namely1×10mm-4).

Specifications:

|

Applications: |

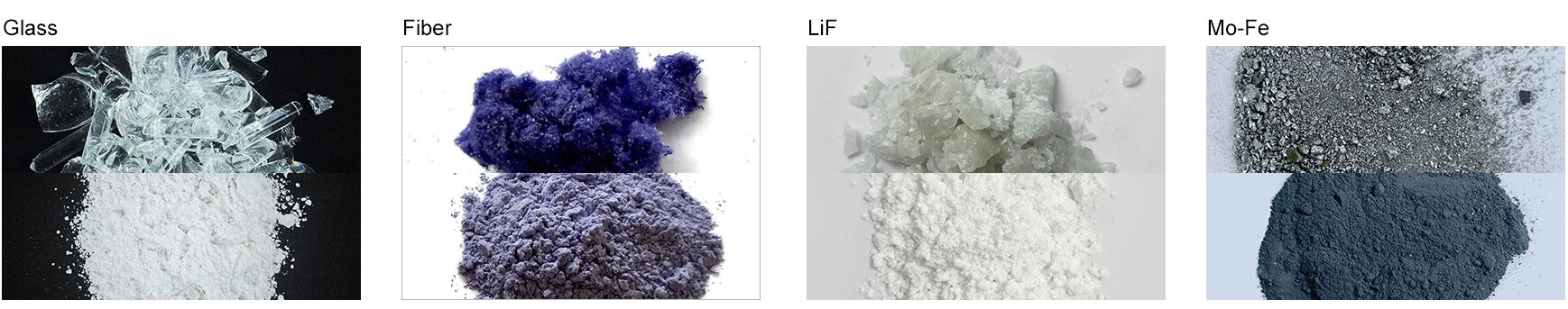

Electronic materials, soil, aerospace materials, batteries, ceramics, minerals, metallurgy, etc. |

|

Applicable samples: |

Soft, hard, brittle, fibrous, dry or wet |

|

Max. feed volume: |

2/3 of the of the grinding jar |

|

Vacuum grinding: |

optional |

|

Feed size: |

soil≤10mm other≤3mm |

|

Final fineness: |

0.1μm |

|

Alternate timing: |

1-9999min |

|

Rotation |

600rpm |

|

Grinding jar: |

250ml、500ml、1000ml |

|

Vacuum jar: |

500ml |

|

Certificate: |

UL、CE |

|

Power: |

220V 1.5kw 50~60Hz |

|

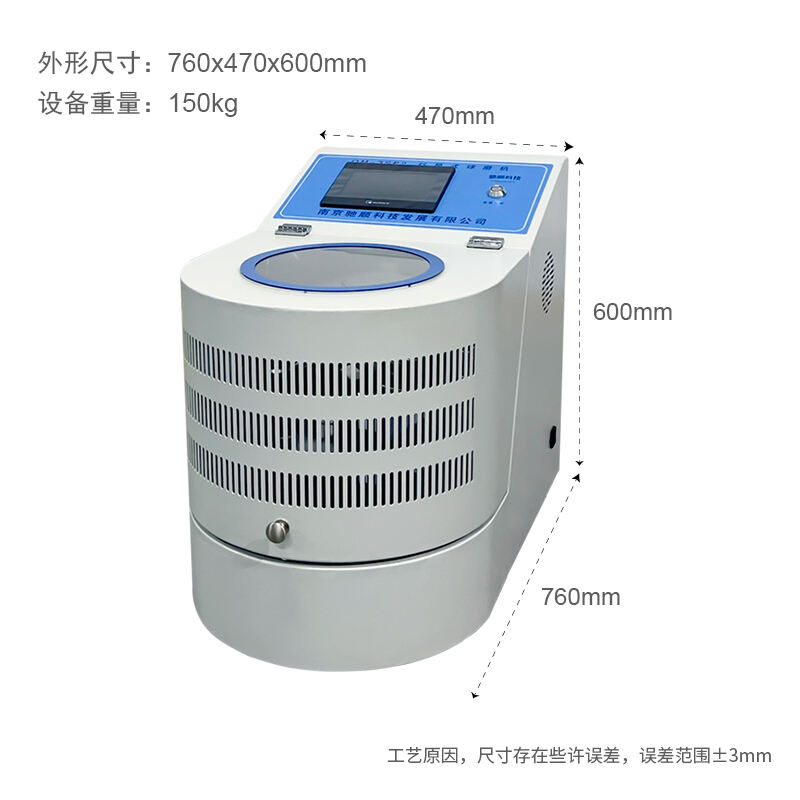

Dimension: |

76*46*67cm 110kg |

|

Data storage: |

120 sets processes |

|

Data monitoring: |

Real time monitoring of operational status, supporting fault alarms |

|

Programmable operation: |

6 sets operation steps supporting edit/delete |

|

Control mode: |

7" HMI touch screen, Multiple operation modes (forward and reverse alternating operation, interval operation, timed operation) |

|

Jar materials: |

Stainless steel, vacuum, agate, zirconia, alumina, PTFE, nylon, tungsten carbide,etc. |

Jar options

Competitive Advantage:

- Factory direct delivery

- Quality assurance

- Best price

- Compact in size

- Complete specifications

- Service Assurance

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

BN

BN

LO

LO

LA

LA

MN

MN

KK

KK

UZ

UZ

LB

LB

XH

XH