Continuous sintering furnace is a type of equipment employed to elevate the temperature of materials, such as ceramics, to extremely high levels during the process referred to as sinterization. The design of the Nanjing Chishun sintering furnace ensures consistent heating material movement, which results in a steady production of high-quality products. In the realm of ceramic production, these kilns are essential.

Manufacturing, as in all regions of the globe, plays a crucial role in the economy and there is always room for improvement in how it is carried out. The period of uninterrupted sintering furnaces. This technology could be dubbed industry 4.0 for heating ceramic materials as it has always been done, just faster and more efficiently now. This involves cutting down on processing time and sometimes using less energy, beneficial for manufacturers and the environment. During traditional sintering, the furnace had to be turned on and off repeatedly to heat up a batch of materials. This period of inactivity not only decreased efficiency but also squandered resources. A Nanjing Chishun high temperature sintering furnace can overcome these obstacles by offering round-the-clock production. This higher level of operational capacities allows manufacturers to produce more in a shorter period, increasing productivity and efficiency.

The Solid-State Reaction, which occurred in the past, was the most time-consuming. Continuous sintering furnaces are changing the ceramic production industry by revolutionizing traditional methods with varying temperature levels due to the use of different heating sources in each batch. These kinds of Nanjing Chishun metal sintering furnace provide a more uniform heat setting, resulting in very consistent outcomes. Having the flexibility to adjust heat parameters for various types of raw materials is likely one of the key strengths and assets of continuous sintering furnaces. The machinery can manufacture a wide variety of ceramic items, ranging from kitchenware to electronic parts, making it a versatile and perfect system.

One of the major challenges in the ceramics manufacturing process is achieving a reliable and top-notch end product. Flaws on the end result are readily noticeable, even with minor shifts in temperature and other factors. Constant sintering furnaces guarantee even and closely monitored heating, thus preventing any defects. The consistent movement and circulation of material in every Nanjing Chishun sintering furnace for sale guarantees that all cooling rates stay uniform throughout transportation, preventing any adverse impact on the quality of the final products. Maintaining a consistent production profile ensures customer satisfaction and decreases waste.

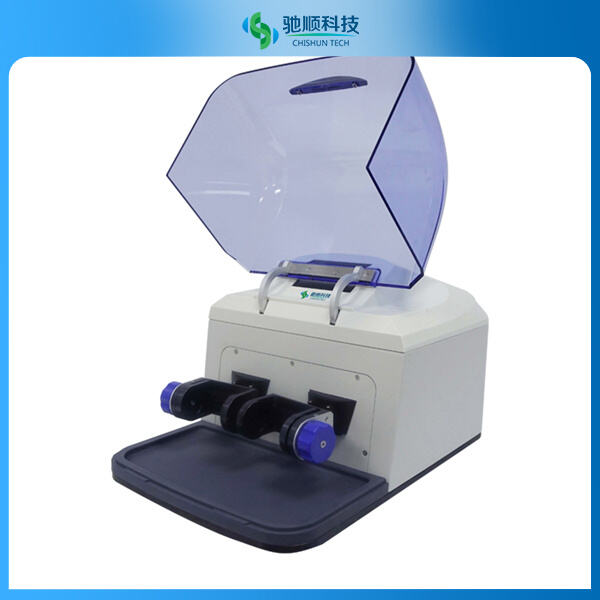

Our products are used Continuous sintering furnacein mining, geology, electronics, metallurgy materials ceramics, chemical industry, medicine, light industry cosmetology protection environmental etc.

We have been a Continuous sintering furnaceproduction that focuses on research, production, and serving. As among the most important Hi-tech Enterprises of Country Torch Plan CHISHUN was home to a group of excellent workers being technical. In addition they hold a true range patents, and in addition collaborated with local teachers of NJU, NUST and HHU.

Our items are Continuous sintering furnace and services, highly efficient, and quiet. They is perfect for collecting particles 4 samples for every experiment) at scientific research institutes and corporate laboratories.

Our team is dedicated to giving you machinery for the Continuous sintering furnace. Every member of all of us does their best plus is responsible for the ongoing work they do. We sincerely wish that our skills and efforts will better work with you do perform.