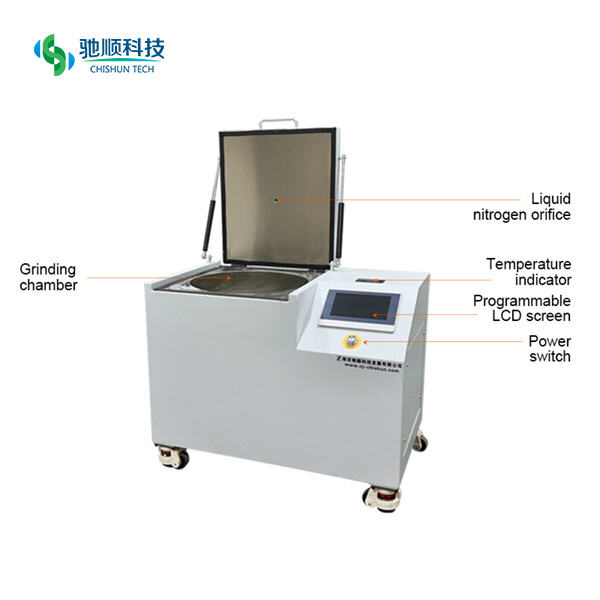

Really, really cold is when the amazing things can come out. Not unlike when you toss your juice box in the freezer and it winds up as a tasty ice pop! But even super-cold conditions can be frozen out of shape, which freeze out of existence, as well. This is where our friends from Nanjing Chishun make their fantastic Cryogenic Mill.

The term cryogenic milling might sound big and fancy, but it’s really just another way of saying freezing and grinding. It is the process of grinding materials at very low temperatures to produce small particles. At those superlow temperatures, materials turn extremely brittle and can be easily shattered. It's not only efficient, it's the best thing for whatever you are grinding up. Nanjing Chishun offers a variety of equipment for material processing including BF Muffle Furnace and Muffle Furnace.

Nanjing Chishun by means of cryogenic grinding can unleash the maximum performance from different materials. Anything from spices and herbs to plastics and rubber can be ground to its desired consistency with cryogenic milling. This results not only in a more even and consistent product, but also aids in preserving the natural flavors and qualities of the material being processed.

“The reduction of particle size is a significant process in the pharmaceutical, food, industrial, and manufacturing sectors. The use of Nanjing Chishun Cryogenic technology in Cryogenic Mill grinding creates the most desirable particle size reduction. Ultra Low Temperature Grinding By cooling the material, about 196 degree below the materials will be crushed but the cooling to extremely low temperature features will become a solid condition and powder.

Time is money, and material processing is no exception. Nanjing Chishun adopts very advanced cryogenic milling technology to make the grinding process more efficient in many aspects. Inferior smoothness of the milled particles can be achieved by reducing the grinding energy required and increasing throughput of materials, the cryogenic milling process is more time and energy efficient. Which also means more material can be processed in less time, higher productivity and lower cost of production.

Cryogenic Milling Technology Univercell® The Universal Cryo-Mill It is the Smallest Cryogenic Mill in its Class.Grinding processes with the highest energy demand based on our cryo-milling technology result in suitably fine particle sizes with ground metalizer.

The potential is limitless when considering processing materials using cryogenic milling technology. Some techniques today for our chilies offered by various machines led us to the Cryogenic Mill Nanjing Chishun It offers running down to very fine powders for pharmaceutical or other uses, but also a milling powder chili for flavoring combination or dish requiring ground spices finely. At very low cold temperatures, materials can be transformed into the perfect viscosity to fulfill these various applications.

Our company is really a cryogenic mill in manufacturing a position to combine research manufacturing, sales, and service. As one of the important Hi-tech Enterprises of Country Torch Plan, CHISHUN possessed the very best technical personnel hold many patents. along with working together with local professors from NJU, NUST and HHU.

Our items are cryogenic millfound in geology, mining, electronics, metallurgy materials, ceramics, chemical industry light industry, medicine, cosmetology, environmental protection, and a whole lot more.

Our instruments are cryogenic mill, full-featured, full of effectiveness plus reduced in noise which make them perfect instruments obtaining particulate samples (four samples every test) in scientific analysis institutes, colleges and universities, plus in business research laboratories.

All of us is aimed at supplying you and hardware of this cryogenic mill. Every person inside our team works diligently and it is responsible for the ongoing work they do. We hope which our knowledge and effort will assist you to create better perform.