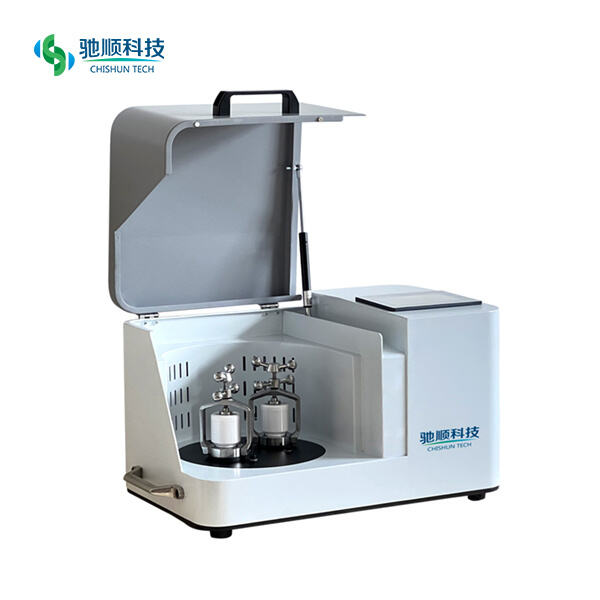

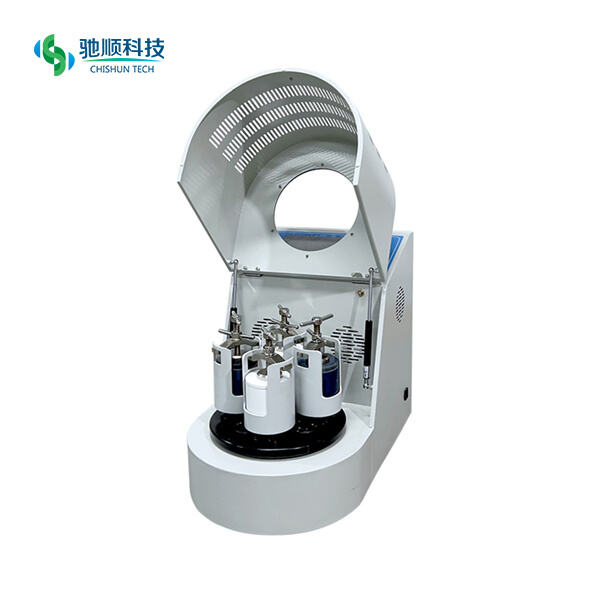

Vertical ball mills are a form of “stirred” ball mill and can be more energy efficient than typical horizontal ball mills. They are vertical in shape and are somewhat similar in appearance to a flintstone for the rolling of steel balls, and the grinding medium May be steel bar or the like. A company developing vertical ball mills is Nanjing Chishun.

With a vertical ball mill design, vertical ball mill slakers are best suited to applications where the lime quality is poor, water chemistry is poor, grit handling is costly or when the processing rate exceeds that achievable in a conventional slaker.

Nanjing Shishun’s ball mill design is only come out from the mechanical design, and its mechanical design is formulated centrically to avoid electrical system inrush current. These mills can crush materials to less than a fraction of a millimetre with the dust getting weep away as the balls combine to cross each other tighter than other systems in the more traditional horizontal ball mills. It means you can finish the work faster, use less energy, and get a more uniform finish, saving you time and money.

There are many benefits to the grinding process carried out by a vertical ball mill. One of the primary advantages of these mills is their efficiency. Due to their vertical arrangement, the production capacity is more than doubled compared to the Columbite device and yields a better final product. Vertical ball mills are not very popular and not the most around however, they tend to be more efficient than ball mills.

Opt for a vertical ball mill if you desire a milling process that is simple and versatile. They are engineered for maximum efficiency and productivity so that you can get more work done in less time than with standard horizontal ball mills. Furthermore, vertical ball mills are not requiring a large installation cost as well as power consumption when large scale and tonnage grinding shall be performed. Also, vertical ball mills are ideal where low net power demand, and high capacity option are required.